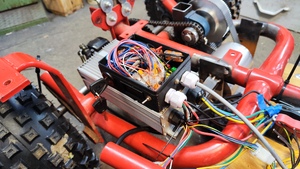

Converting a sturdy children’s pedal go-kart (Kettcar) into a 3000 W fully electric vehicle - faster, easier, and more fun than pedaling.

Originally pedal-powered, the Kettcar is now fully electric and capable of pulling trailers or driving around the yard with minimal effort.

Motivation

The original Kettcar was extremely sturdy but heavy, with only 3 gears and a poor brake system. Pedaling required significant effort, making it impractical for children and resulting in years of disuse.

Given its strong steel frame, it was an ideal base for conversion into a usable and enjoyable electric vehicle.

Specification

- Top speed: 30 km/h

- Range: ~2 h (estimate, untested)

-

Features:

- 3 programmable speed levels + hidden sport mode

- LED headlight

- Chain and belt guards

- Adjustable seat

- Hydraulic brake

- Planned: Bicycle trailer hitch, tire guards, paint job

Components

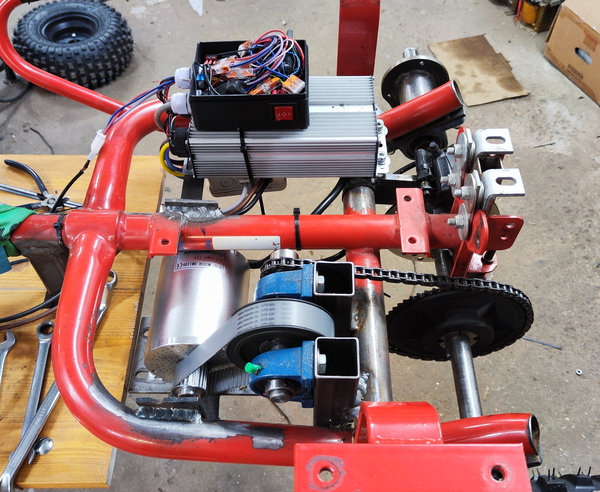

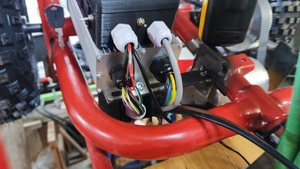

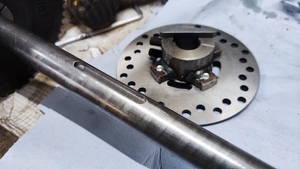

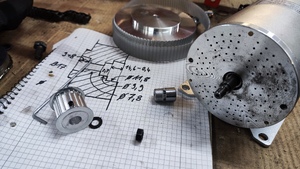

Mechanical

- Frame: Original Dino Cars Kettcar steel frame

-

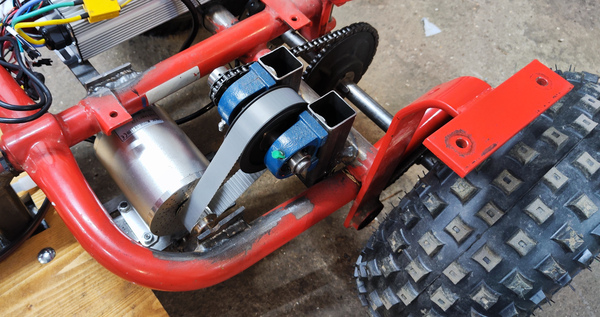

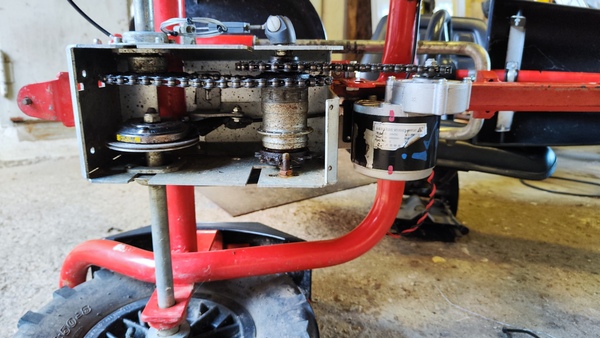

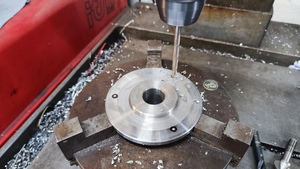

Drivetrain:

- 20 mm intermediate shaft for high gear reduction because of high-RPM motor in combination with large tires

- Stage 1 - belt drive:

- Motor pulley: AT5 Z22

- Shaft pulley: AT5 Z64

- Belt: AT5 B25 500 mm (Z100)

- Stage 2 - chain drive:

- Shaft sprocket: Z14

- Axle sprocket: Z57

- Chain: 06B-1 (3/8″ × 7/32″)

- 25 mm rear axle

- 2x bearing block

- Custom wheel hub fixed (key)

- Custom wheel hub free spinning (2x bearing)

- Custom brake disk adapter

-

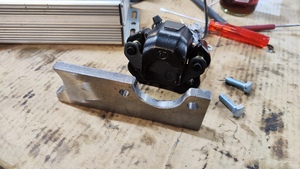

Brake:

- Single hydraulic disc brake (rear axle, go-kart kit)

-

Tires:

- Rear: ATV complete wheels 16×8-7 “knobby”, 3-hole

- Front: Original Kettcar wheels

Motor & Control

Motor

- Origin: Common “3000 W Go-Kart kit” motor (widely available)

- Power: 3000 W

- Voltage: 72 V

- Max DC current: 50 A

- Speed:

- Rated: 4900 rpm

- No-load: 6600 rpm

- Torque: 5.44 Nm

- Price: ~140 EUR

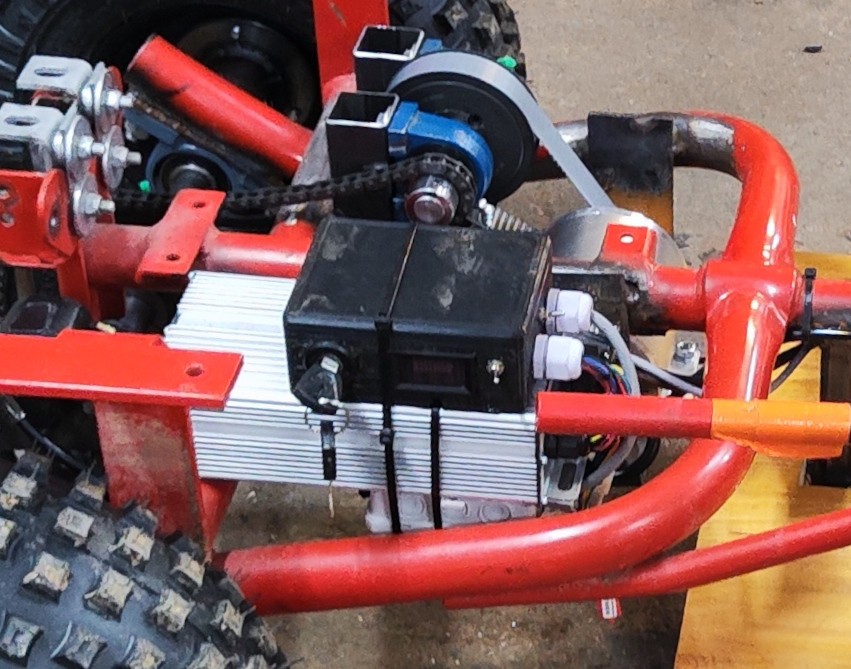

Motor Controller

- Generic 18-MOSFET BLDC controller

- Power: 3000 W

- Phase current: 80 A

- Rated Voltage: 48/60/72/84 V

- Price: ~30 EUR

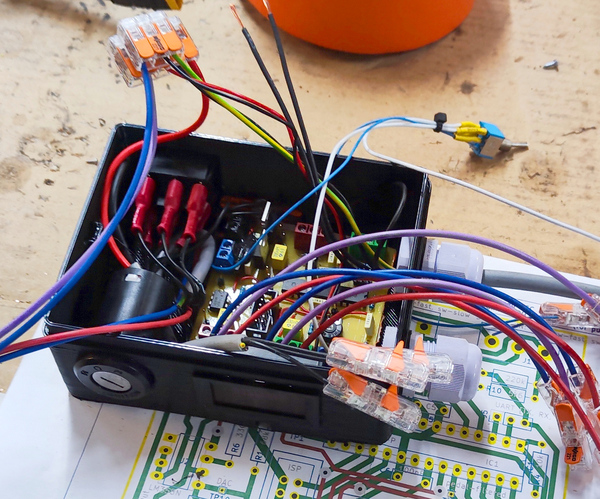

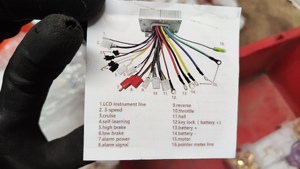

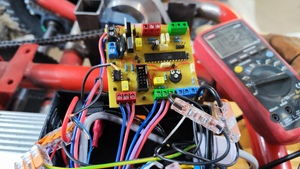

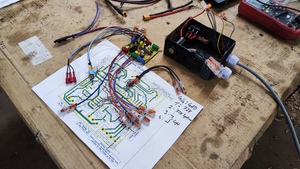

Control Box

- Purpose: Custom board connected between pedal and controller for smoother throttle and fully customizable speed modes

- MCU: ATmega8

- Key features:

- Throttle remap

- Ramp-up

- 3 speed levels + sport mode

- Reverse + headlight switch

- Battery indicator

- Build: CNC-milled single-sided PCB, through-hole, 3D-printed housing

- Firmware: GitHub - throttle-tune

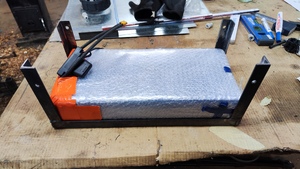

Battery

- Type: Commercial Li-ion pack

- Rating: 72 V, 25 Ah (1.8 kWh)

- Max current:

- Peak: 180 A

- Continuous: 60 A (60 A BMS)

- Split BMS (separate charge and discharge port)

- Charger: 84 V, 4 A

- Cell arrangement: 20S 9P (180 cells)

- Price: 563 EUR

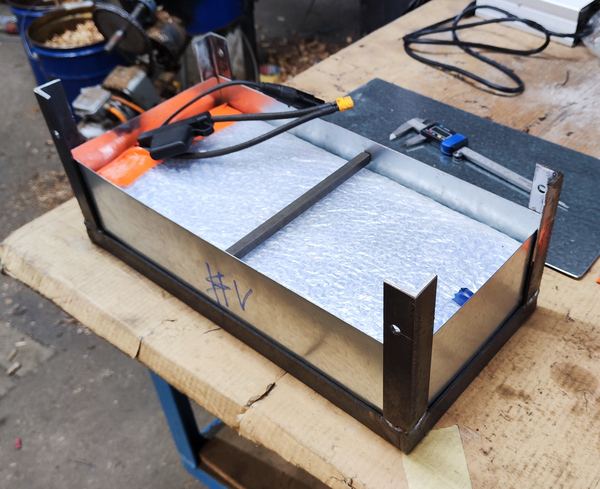

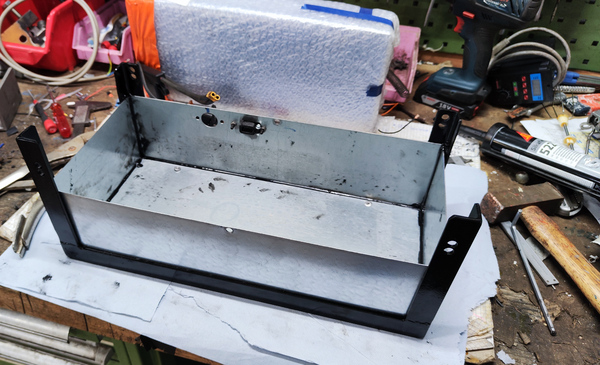

- Mounted in custom angle iron frame with sealed sheet-metal housing for front-end exposure protection

- Integrated fuse and XT60 connector

Technical Notes & Assets

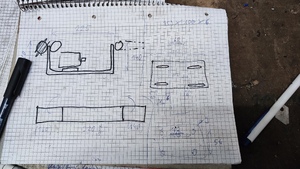

Drivetrain calculation

To design the custom drivetrain, I prepared a spreadsheet to size belts, pulleys, and gears correctly and to estimate the achievable speed of the vehicle.

This provides a quick overview of the drivetrain concept and expected performance.

The sheet also helps to keep track of different gear ratios and configurations that were tested during the design process.

Parts List & Prices

A complete parts list - including prices, total costs, and purchase links - was also created for this project.

Technical Drawings

While most parts were built from simple sketches, a few were designed in CAD to make dimensioning easier. Some are included here for reference and documentation:

All Drawings: kettcar_technical-drawings.pdf

Custom Control Board

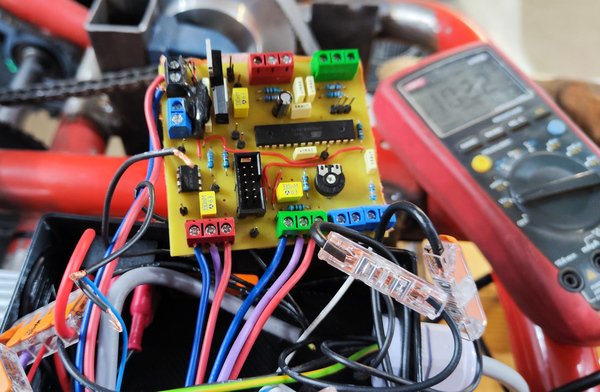

The cheap 3000 W BLDC controller used here had the same problem as in my Electric Lawn Tractor, where it was previously installed:

Only a tiny range of the pedal was effective, making acceleration jerky and hard to control.

To fix this, I designed a custom throttle adapter PCB that rescales the pedal signal, adds smooth ramp-up, and allows multiple configurable speed modes.

For the Kettcar build I simply reused this board - it completely solves the throttle issue and it was even extended with features specific to this project.

- Purpose: Smoother throttle response, fully customizable speed modes

- MCU: ATmega8

-

Features:

- 3 speed levels + hidden sport mode

- Throttle remap (uses full pedal range)

- Ramp-up (smooth acceleration, prevents stuttering)

- Reverse + Headlight control

- Buzzer alerts

- Battery voltage indicator

- More details & Firmware: GitHub - throttle-tune

For more details about this PCB, visit the repository containing the PCB files and the firmware: GitHub - throttle-tune.

Pedal Assist Version

The very first idea was to add a simple motor for extra pedaling support with minimal effort, using a 24 V, 300 W brushed DC motor on the original chain drive.

While it worked, it was underpowered, overheated, dangerous, and ultimately impractical. It turned out no one actually wanted to pedal anymore at all anyways. This led to the switch to a full-electric 3000 W system, discarding the pedals completely.