Transforming an old lawn tractor into a versatile electric vehicle for practical yard work.

This project focuses on converting a decommissioned damaged lawn tractor into an electric machine designed for various tasks, from towing trailers to carrying loads. With multiple attachments planned.

Motivation

The engine of a 10-year-old lawn tractor was damaged beyond repair and a new tractor purchased. Rather than simply discarding the old tractor, this project was born to use the chassis and transmission of the tractor and convert it into an versatile electric vehicle for use around the garden, giving it a new purpose.

Specification

- Top-speed: 40 km/h

- Range: >30 km (untested)

-

Current Features:

- 90 L utility tray

- Bicycle trailer hitch

- 230 V outlet (2200/4400 W sine wave inverter)

- Water pump attachment

-

Future Features (Work in Progress):

- Sweeper attachment

- Snow plow

- Tiltable utility tray

- Lights

Components

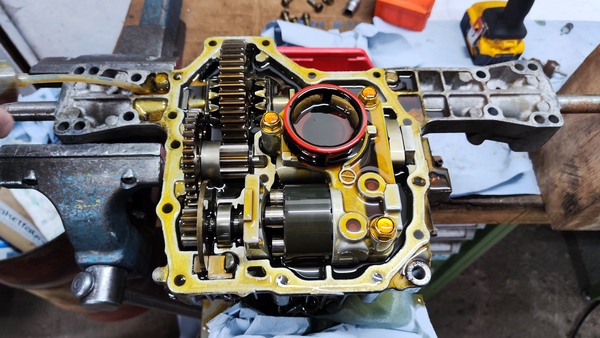

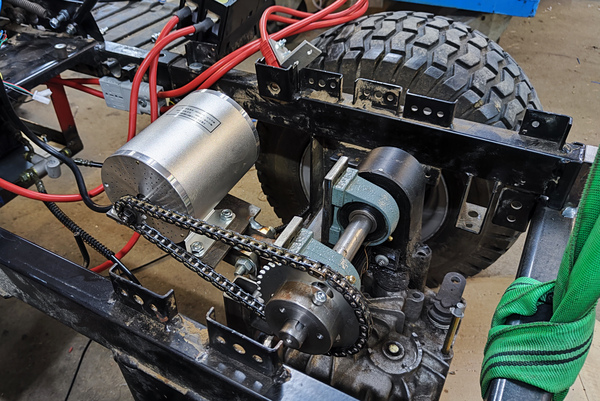

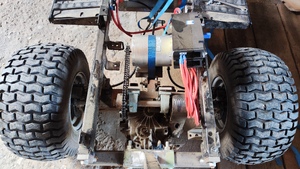

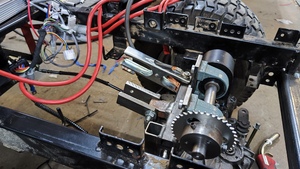

Mechanical

- Frame: From lawn tractor Iseki CM 7226 H

-

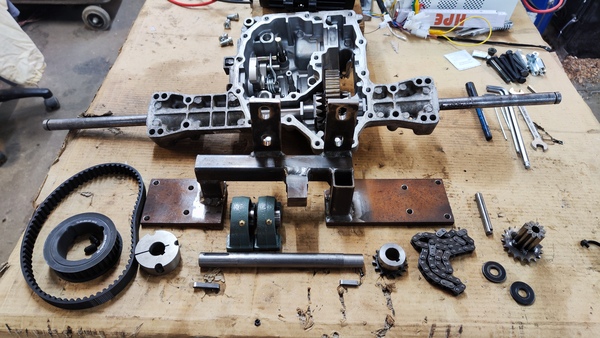

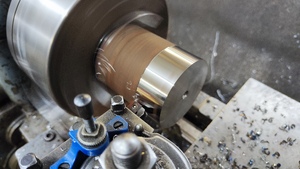

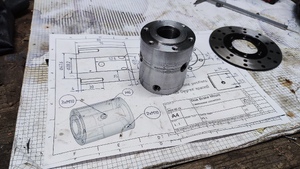

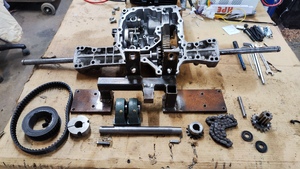

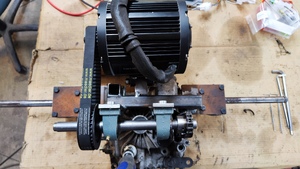

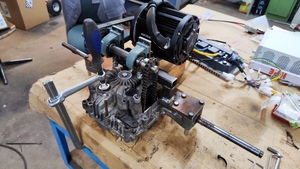

Drivetrain:

- Custom intermediate shaft connecting motor to old hydrostatic transmission, utilizing the differential

- Timing Belt Drive:

- Motor Pulley: 8M Z22 20 mm

- Shaft Pulley: 8M Z56 20 mm

- Belt: HDT 8M Timing Belt 20mm 656 mm (Z82)

- Chain Drive:

- Shaft Sprocket: Z15

- Gearbox Sprocket: Z18

- Chain: 06B-1 (3/8’ x 7/32’)

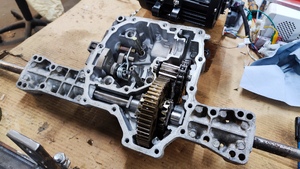

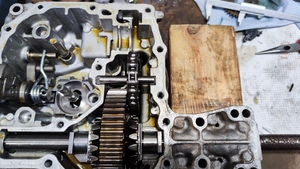

- Gearbox:

- Spur Gear (Shaft with sprocket for chain): Z10

- Differential Spur Gear: Z54

-

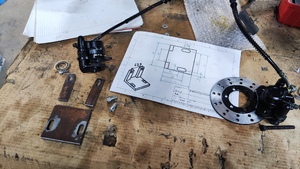

Brakes:

- 2 Disk Hydraulic Brake Set for ATV

- Custom adapter for attaching brake disk to rim

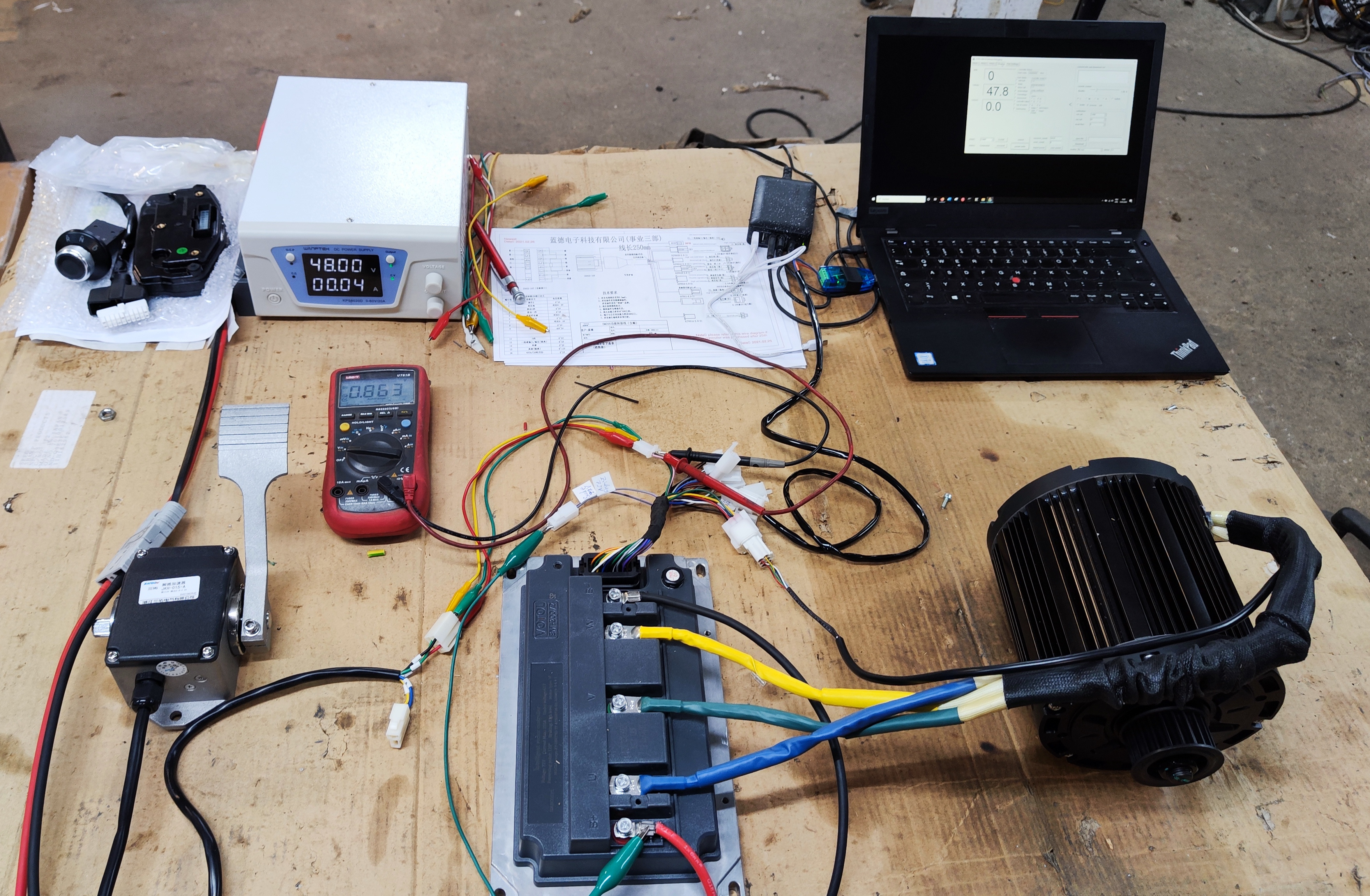

Motor

- Name: QS Motor qs138 90h

- Power:

- Peak: 13.5 kW

- Continuous: 7.5 kW

- Rated: 4 kW

- Voltage: 72 V

- Max DC Current: 200 A

- Rotational Speed: 4000 rpm (6500 with flux weakening)

- Torque: 14.3 to 72 Nm

- Pole Pairs: 5

- Price: 350 EUR

Controller

- Name: Votol EM200-2SP

- Max Power: 18 kW

- Phase current: 600A

- DC current: 200A

- Rated Voltage: 72V

- Weight: 2.4 kg

- Efficiency: 92 %

- Price: 360 EUR

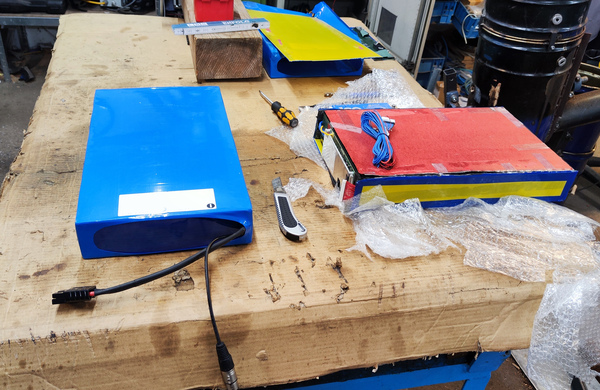

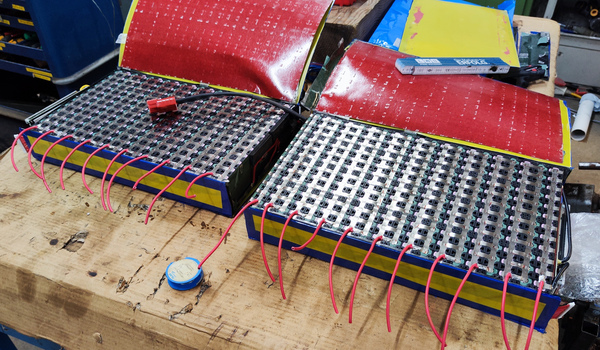

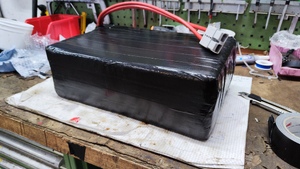

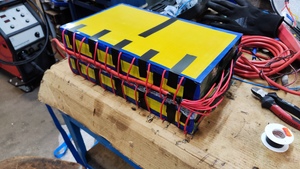

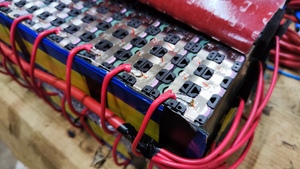

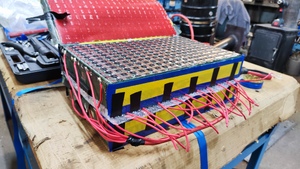

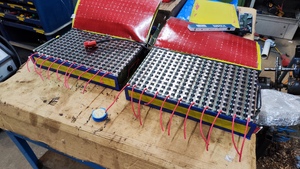

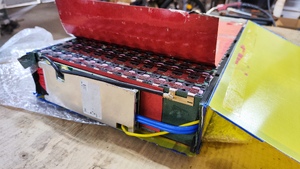

Battery

-

Stats:

- Rating: 72 V, 60 Ah (4.3 kWh)

- Cell arrangement: 20S 24P (480 Cells)

- Charge Voltage: 84 V

- Charge current: 15 A (1200 W)

- Type: Two bought Li-ion packs modified with custom BMS

- Battery cell: SINC ISR18650 2600

-

Original Pack:

- Rating: 72 V, 30 Ah, 2160 Wh

- Max current:

- Discharge: 60 A

- Charge: 5 A

- Cell arrangement: 20S 12P

- Price: 750 EUR

Note: I bought two of the original packs and rewired them in parallel for higher current output and to enable regenerative charging, as the original split-port BMS didn’t support parallel connection or regenerative braking.

-

Battery management system (BMS):

- Manufacturer: Daly bms

- Name: Smart BMS BT+CAN+WIFI 8-24S 150A

- Max current:

- Discharge: 150 A

- Charge: 100 A

- Type: Any cell type, Arrangement 8 to 24S

- Features:

- Over charge protection

- Over discharge protection

- Over current protection

- Balancing

- All values adjustable via app

- Price: 105 EUR

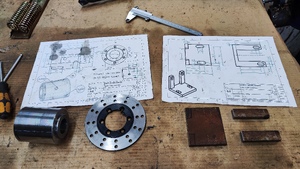

Technical Drawings

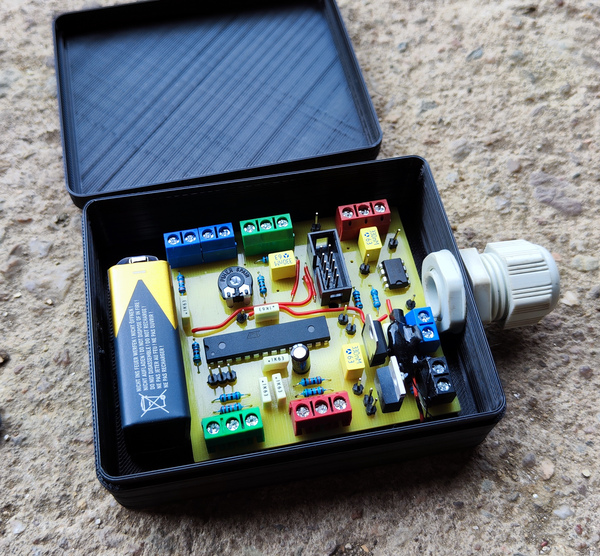

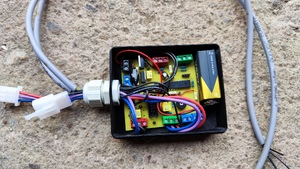

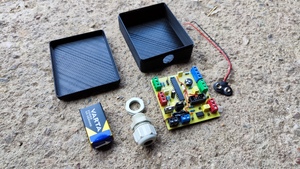

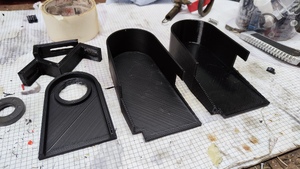

All 3D-printed parts, like the PCB housing and chain cover, were designed in FreeCAD and printed. Some metal parts, like the brake system, were also designed beforehand to serve as guides for manufacturing:

Difficulties

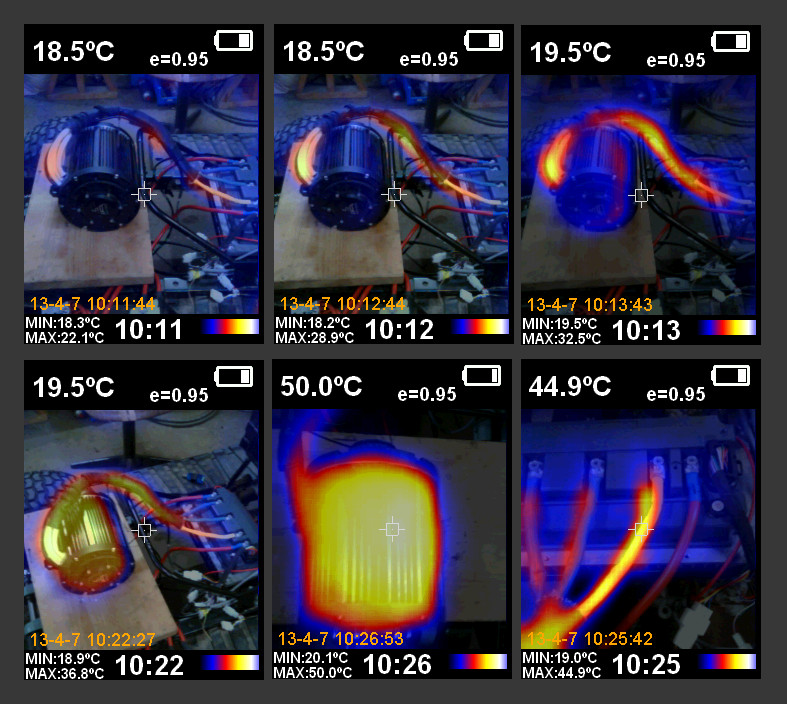

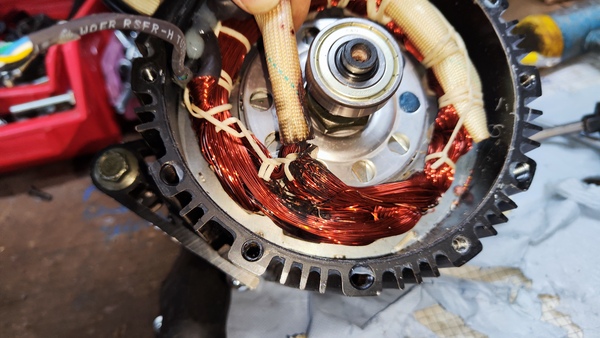

Motor Defect

Problem:

During the first few test runs, the motor started vibrating abnormally and quickly overheating. After trying various controller settings and running diagnostics, I decided to open the motor. It turned out that several windings were burnt and partially shorted, which caused excessive heat as the shorted windings constantly applied braking force every revolution, resulting in high current flowing to the terminals and back into the motor.

The cause appeared to be loose windings and vibrations that wore down the insulation on the windings, leading to shorts.

Solution:

QS Motor kindly provided a free replacement for the faulty motor.

While waiting for the new motor to arrive, a smaller temporary motor was installed to keep the vehicle functional during the debugging period.

Bad Motor Controller

Problem:

The motor controller for the smaller BLDC motor, used temporarily while waiting for the replacement motor, didn’t function well with the throttle and high battery voltage.

The throttle’s effectively used travel range was extremely short, which made controlling the vehicle speed difficult, resulting in jerky, erratic acceleration switching between 0 and 100 %, making the ride very shaky.

Solution:

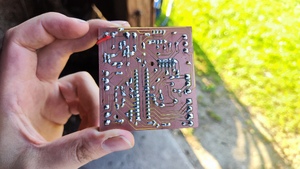

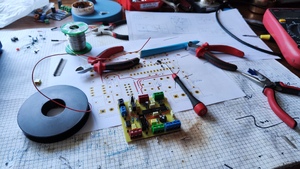

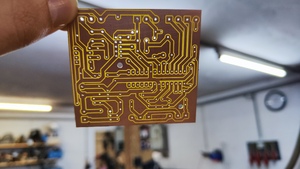

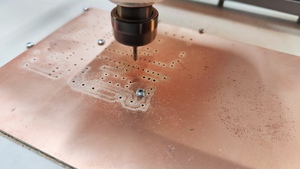

To fix this, I designed and built a custom PCB with a microcontroller and custom DAC to rescale the throttle signal before passing it to the controller. This modification added three speed levels, adjustable with a switch, and allowed full throttle range usage with a ramp-up feature for smoother acceleration. The PCB was designed in KiCad and milled on a CNC router.

Schematic of the pcb for manipulating an analog signal

For more details about this PCB, visit the repository containing the PCB files and the microcontroller source code: GitHub/throttle-tune.