An old sliding gate got upgraded with electric motors - Rework after 7 years

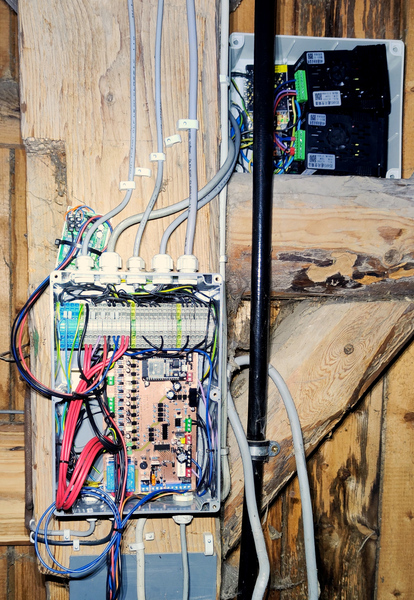

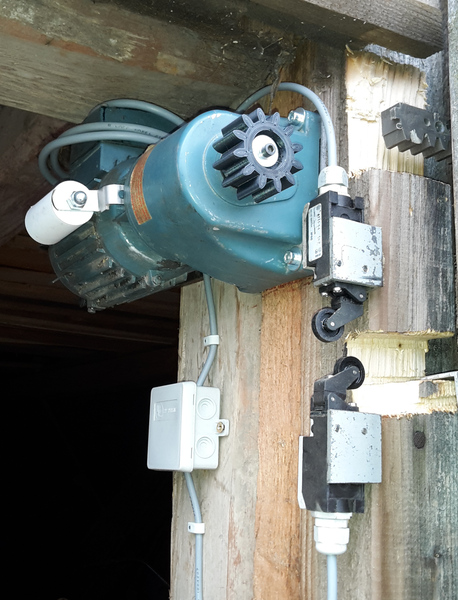

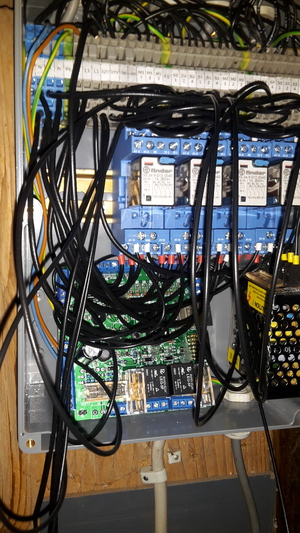

The original automated sliding gate project, built in 2018, has been completely reworked after 7 years of use. While the motors and wiring remained the same, the control system was redesigned from the ground up.

V1 Performance & Lessons Learned

The original built system performed pretty reliable for 7 years, making daily life much easier. However, over time, a few issues and missing features became apparent:

- Startup stress – Motors engaged too abruptly, wearing gears, racks and mounts

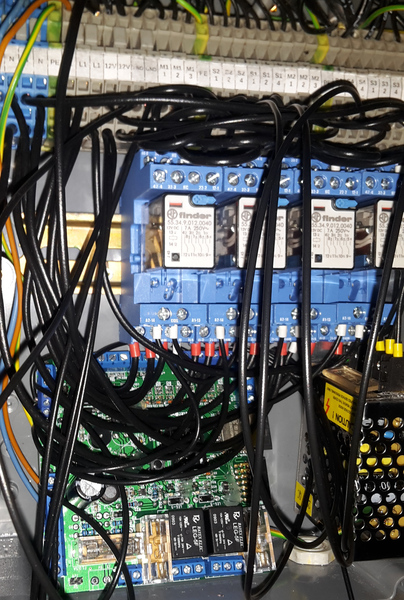

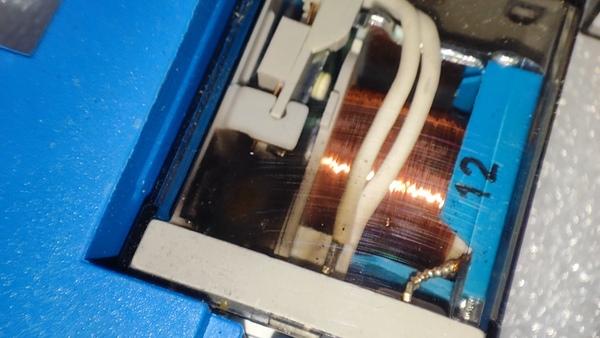

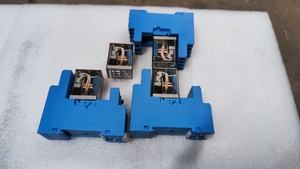

- Relay wear – 12V relays degraded, causing unreliable operation

- Cold start issues – Thickened gearbox grease in the winter prevented movement due to weak starting torque

- EMI problems – Sparks from relays forced external PCB placement

- Limited control – No acceleration and torque control, or overload detection

- Missing safety features - insufficient light barrier, no locking mechanism

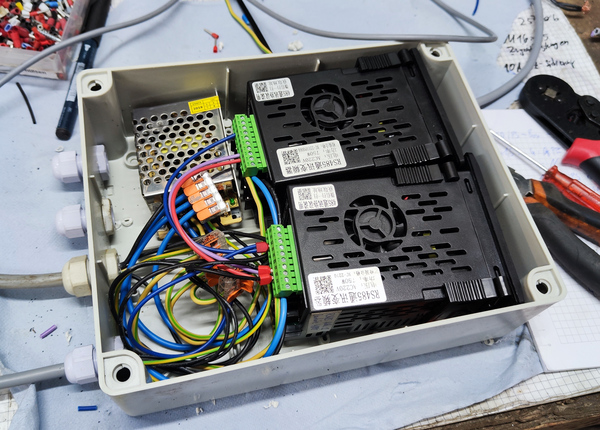

V2 addresses these with a custom PCB and VFD-based motor control, improving reliability and adding new features.

What’s New in V2

-

VFD-controlled motors instead of relays and capacitors

- Smooth starts

- Precise speed and torque control

- Overload detection

-

Custom PCB

- Isolated microcontroller from long cables & VFD noise

- Integrated RS485 interface

- Servo interface for gate locking

- Encoder support for precise position tracking

-

New features & planned upgrades

- Multiple Light barriers

- Overload detection

- Servo motors for locking the gate

- Actual position tracking using encoders

Specification

- Power supply: 230 V AC

-

Control Interfaces:

- Buttons on gate

- Buttons on control box

- Remote control (radio transmitter)

Web interface

- Open / Closing speed: adjustable from 0 to 2 m/s

Components

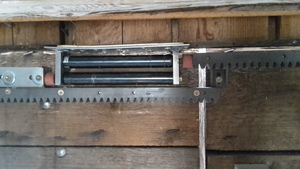

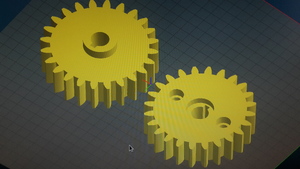

Mechanical

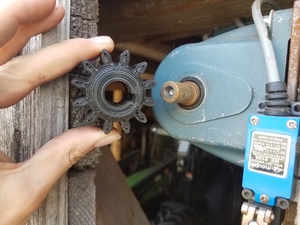

- 2x 3D-printed gear

- 2x Toothed rack

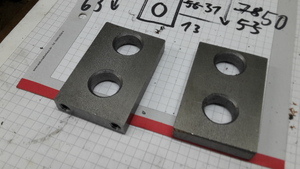

- 4x Custom end position damper

- 2x Custom guide roller

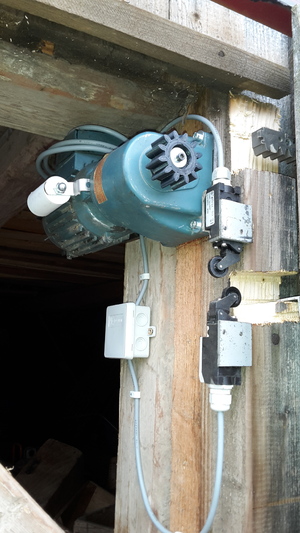

Motors

- Power: 0.3 kW

- Voltage: 400 V

- Frequency: 50 Hz

- Type: Three-phase asynchronous motor

- Connection: Now VFD-controlled (previously capacitor-based)

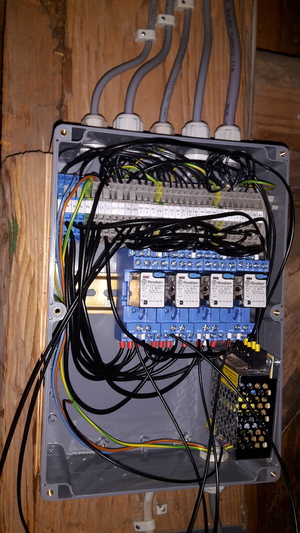

Control System

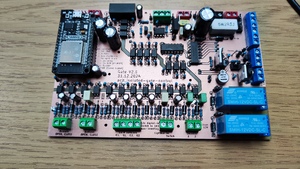

- Custom PCB with ESP32 microcontroller

- Motor control via VFDs (instead of relays)

- Sensors:

- Limit roller switches

- Photoelectric barrier (new in V2)

- Encoders tracking motor position

- Servo-controlled locking mechanism (new in V2)

- RS485 interface (new in V2)

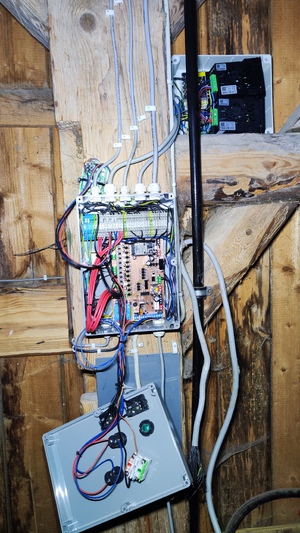

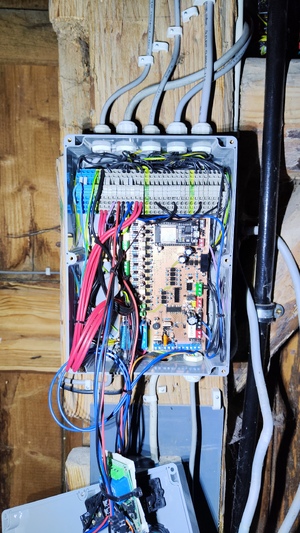

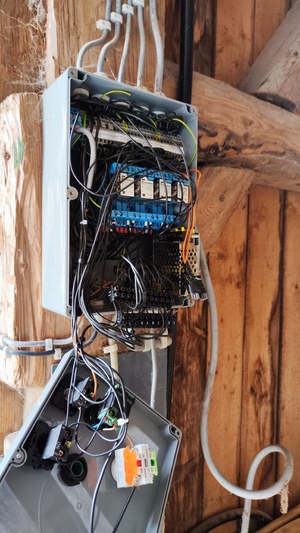

Electrical Overview

The wiring of all components is documented in the following diagram:

Full Document: V2.0_wiring-plan.pdf

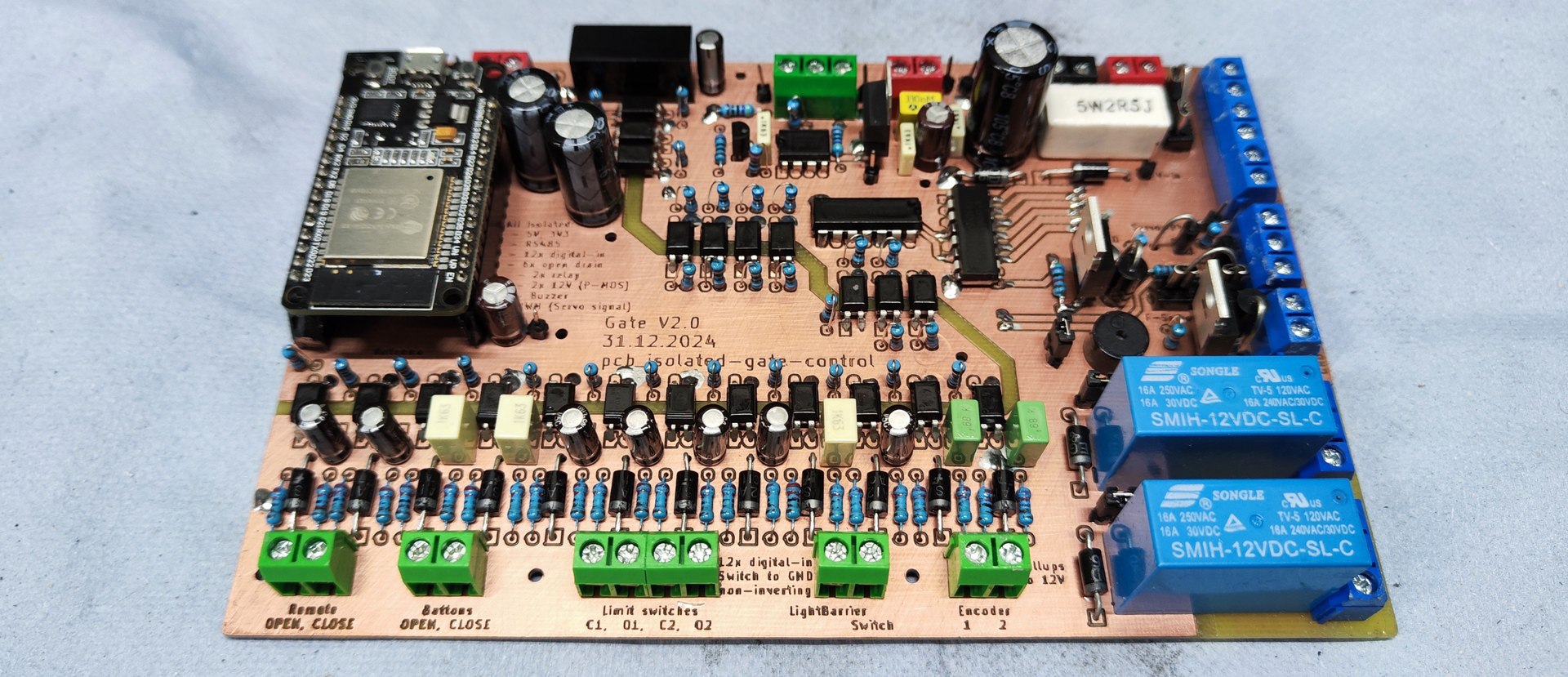

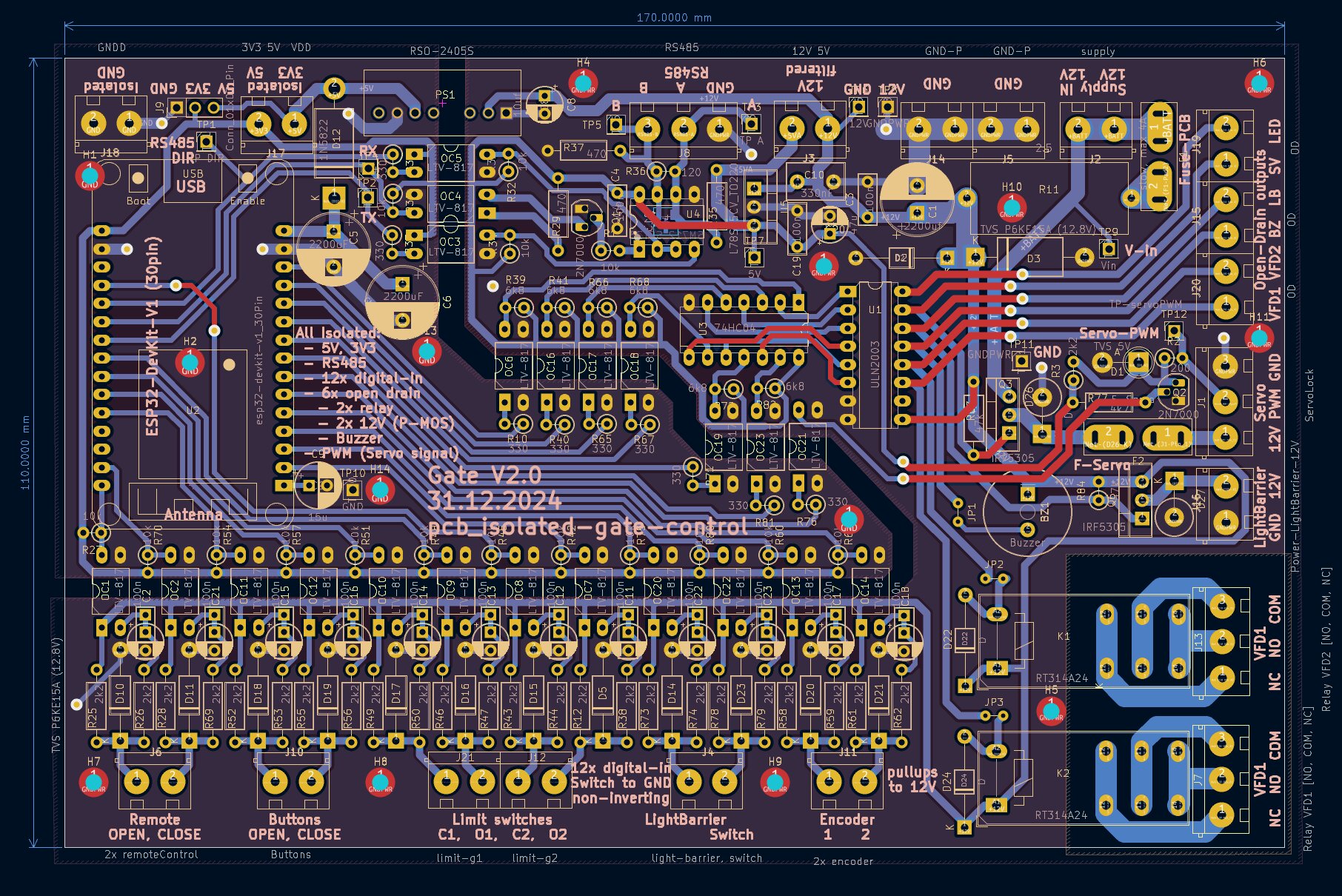

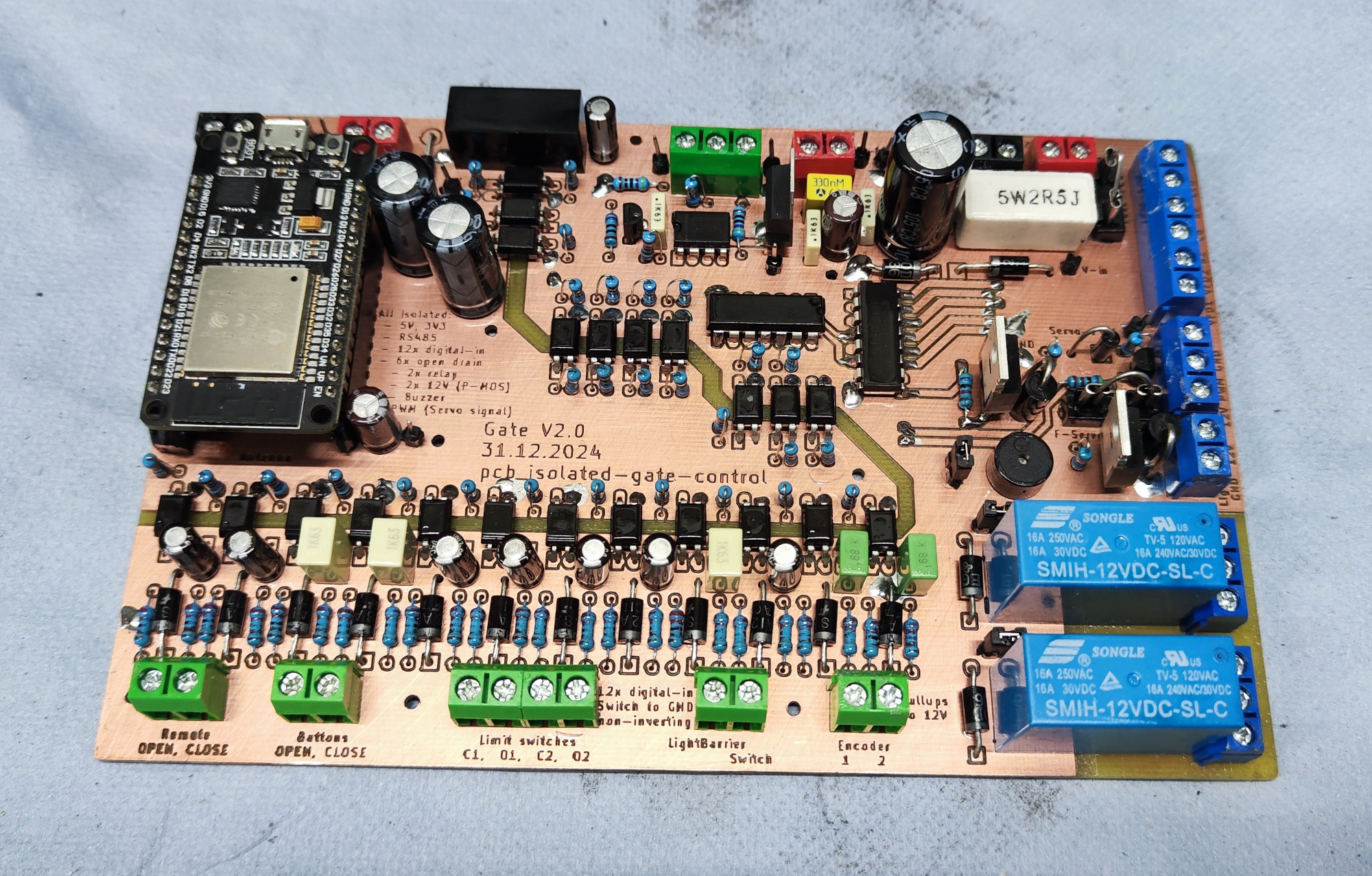

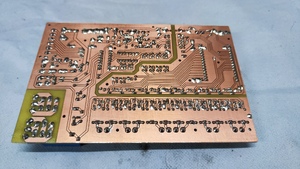

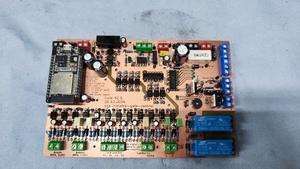

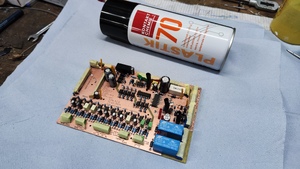

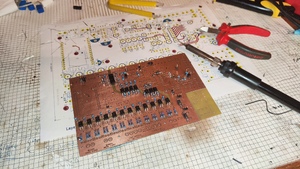

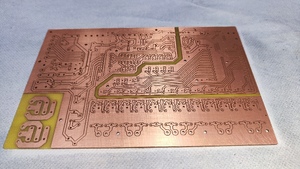

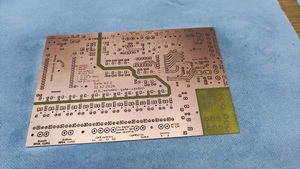

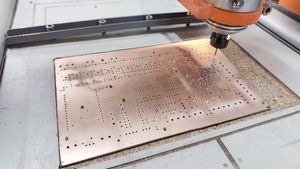

Control PCB

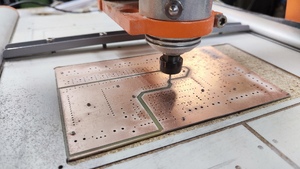

The custom PCB and firmware are available here: GitHub/gate_fw.

Designed specifically for this project, the PCB replaces the previous multipurpose board. It was CNC-machined for quick availability. The core features are:

- Optical isolation of the microcontroller

- EMI safe using integrated filters and protection

- Isolated RS485 interface for controlling the VFDs

- Built-in servo control

Schematic

Complete Schematic: schematic.pdf

Layout

3D Model

Firmware

The Firmware and the PCB design are versioned and available in the repo Github/gate_fw. The ESP32 was programmed in C++ using ESP-IDF.

Videos

(New videos with V2 coming soon)

First Open (Old System)

2018.02.06

First Close (Old System)

2018.02.06