Retrofitting an old loader wagon so it fills buckets with wood-chips at the press of a button.

Motivation

Current situation

We don’t have a chip-fired heating system yet, but we still wanted to use some chips alongside firewood. The workaround was to dump chips on the floor and fill buckets by hand once a week (about ~25 buckets in one session). It worked, but only as a temporary workaround.

Problems

- Mess → chips everywhere → constant cleanup

- Dust → health risk, not great in the hall

- Heavy work → loosen, shovel and lift ~25 buckets in one go

- Slow → loosening layers + filling takes real time

- Space → big pile blocks space in the hall

- Compaction → chips bind into a solid layer; must be broken up before shoveling

- Overall → working with buckets is not elegant, but it kept things running for now.

This is a temporary bridge until a proper chip-heating system is installed.

Idea

Repurpose an old loader/forage wagon instead of scrapping it: Use the scraper floor, add an auger, and fill buckets with one button press.

Why this makes sense (for now)

- Semi-automatic and effortless → place bucket, press button

- Less dust → fills straight into the bucket; no loosening compacted chips, no shoveling

- Cleaner → no chips on the floor

- Refillable → load at a remote pile with the front loader

- Portable → park it where it’s convenient

- Reversible → bolt-on attachment; wagon (incl. pickup) stays usable later

Result (second test):

Components & Specs

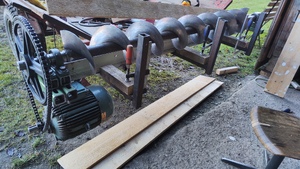

Mechanical

-

Base wagon – HAGEDORN

- Type: loader/forage wagon

- Year: ~1966

- Capacity: 4 t

- Features: scraper floor, pickup (kept)

-

Auger

- Diameter: Ø 250 mm

- Pitch: 250 mm

- Length: 2 m

- Flight: right-hand (R)

- Inner pipe: 60.3 × 3.65 mm (2″ OD)

- Price: 260 EUR

-

Bearing blocks (40 mm UCP)

- Count: 3× total → 2× fixed, 1× floating

- Radial rating (each): 23 kN dyn / 16 kN stat

- Axial capability (each): 3–4 kN (≈20% of radial)

-

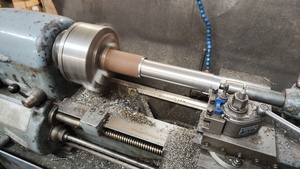

Turning parts

- Custom drive shafts and adapters (motor, auger, PTO)

- Taper-lock seats and 40 mm bearing journals

-

Side walls & sealing

- 8× reclaimed wooden interior doors + OSB panels for side wall paneling (chip-tight)

- 2× 60 cm red street broom brushes as rear scrapers/seals where the scraper bars pass

- Old potato sacks packed into the corners for additional sealing

Drivetrain - Scraper-floor drive

-

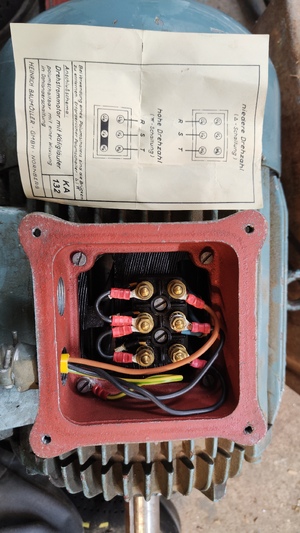

Motor: 3-phase Dahlander

- Manufacturer: Baumüller Nürnberg

- Power: 1.1 / 2.2 kW

- Speeds: 460 / 920 rpm

- Voltage: 380 V

- Frequency: 50 Hz

- Resulting speeds: PTO ~160 / ~320 rpm

- Sprockets: z12 → z35

- Shafts: 32 mm motor, trailer PTO (custom adapter; chain blade on old PTO fork)

- Chain: 10B-1

Drivetrain - Auger drive

-

Motor: 3-phase Dahlander

- Manufacturer: Baumüller Nürnberg

- Power: 1.1 / 2.2 kW

- Speeds: 460 / 920 rpm

- Voltage: 380 V

- Frequency: 50 Hz

- Resulting speeds: auger ~73 rpm

- Sprockets: z12 → z76

- Shafts: 32 mm motor, 40 mm auger

- Chain: 10B-1

Controls & Wiring

-

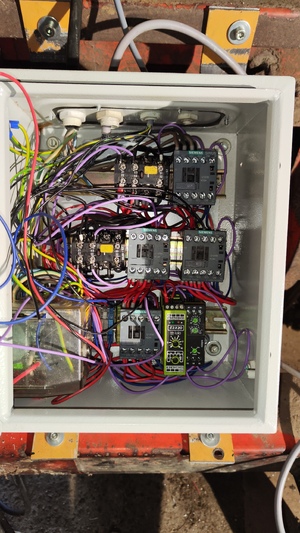

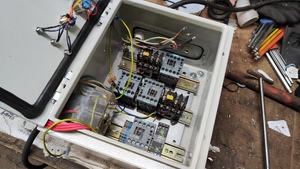

Contactor cabinet

- Devices: 6 contactors, 2 time-delay relays

- Functions: Dahlander 2-speed (scraper), auto-reverse auger (0–1 s adjustable), interlocks & timeouts

- UI: Main power switch, latching power toggle, 2 indicator lights

-

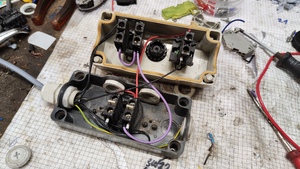

UI box

- Controls: Run (auger), AUTO/MAN (scraper), scraper speed

-

Wiring

- Motors:

- 7G0.75 mm² for scraper (Dahlander)

- CEE 16 A outlet for auger motor

- Supply: CEE 16 A, 5×2.5 mm²

- UI harness: 9×0.5 mm² to rear UI box

- Motors:

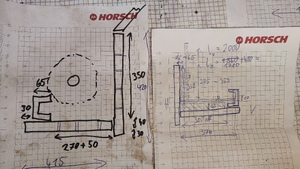

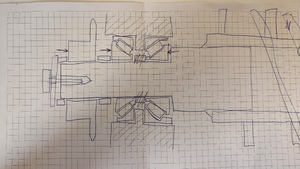

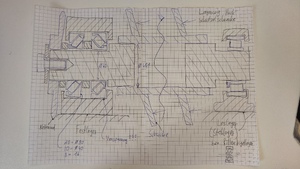

Planning

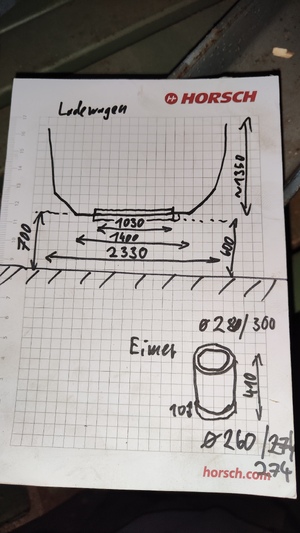

This project was modeled in CAD first.

A simplified trailer model with only the relevant features and an exact attachment design was created.

This made it possible to try different arrangements and positions, check clearances and mounts, and settle the layout before building.

sanity-check of auger rpm:

Technical Assets

Part drawings

Only the parts that benefited from exact dimensions were built from CAD drawings; the rest were straightforward workshop parts built directly from the model and measurements.

Drivetrain calculation

A small spreadsheet was used to try different motor/ratio/chain options with available and bought parts, the final choices are highlighted.

Electrical schematic

Features

- Emergency stop (cut all power)

- Main power switch (supply isolation)

- Indicator lamps: Turned ON / Enabled, Disabled / Fault

- Auger control: forward run, reverse-current braking (plugging) with adjustable timer

- Interlocks: electrical + mechanical FW/REV; Dahlander bridge/line

- Scraper control: AUTO / MAN selector

- Dahlander speed-select (scraper): bridge → line

Contactor circuit test:

Testing the contactor circuit after initial wiring