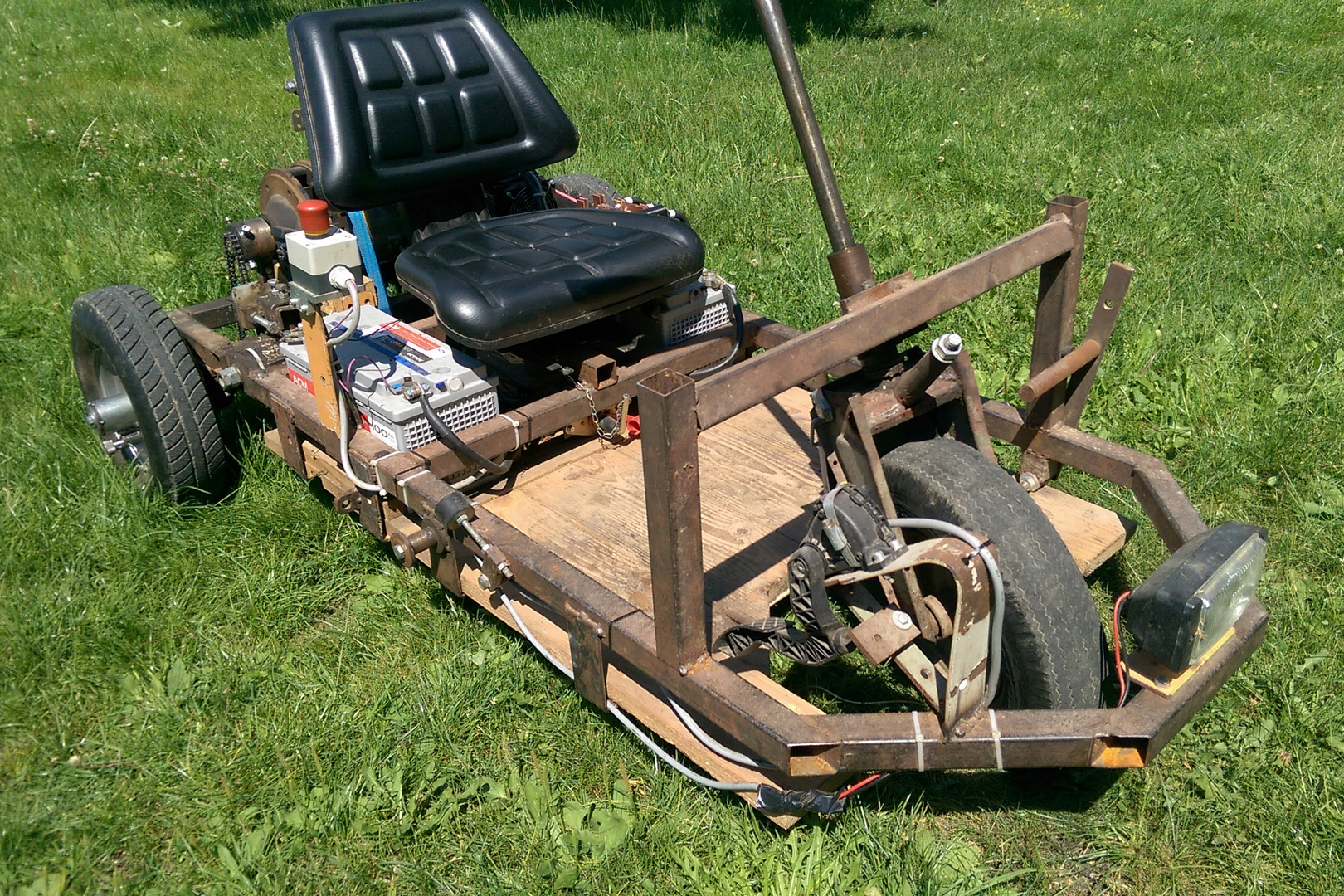

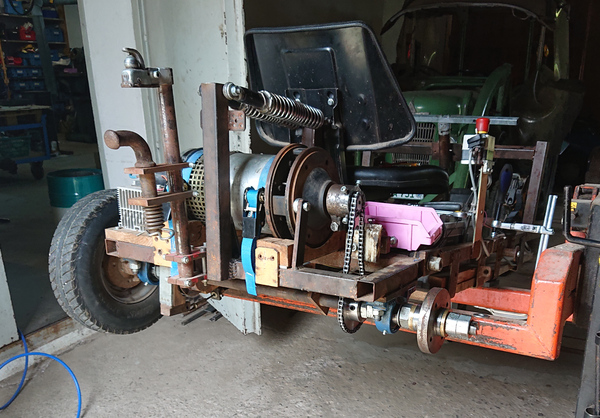

Homemade Electric Kart using a 2,9 kW Forklift Motor

Specification

- Top-Speed: 35 km/h forwards and backwards

- Weight: 240 kg

- Turning radius: 0,5 m

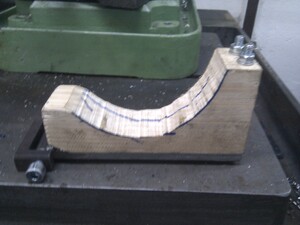

- Brake: Rear only, wooden block

- Suspension: Rear swing arm only Features

- Switch for selecting driving direction

- Switchable differential-lock

- Front light

- Trailer hitch

Components

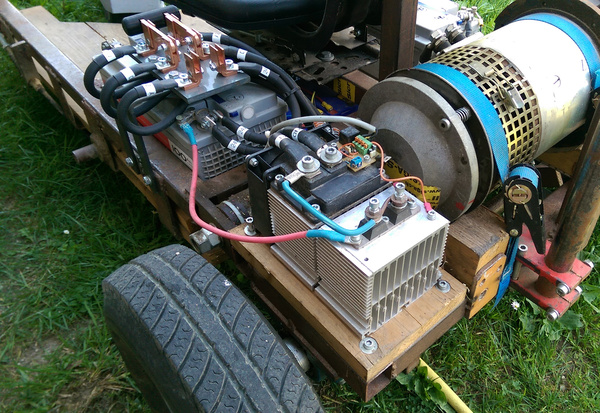

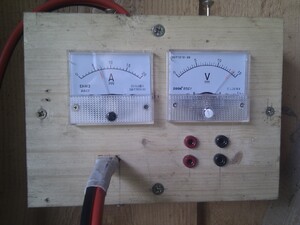

Electrical

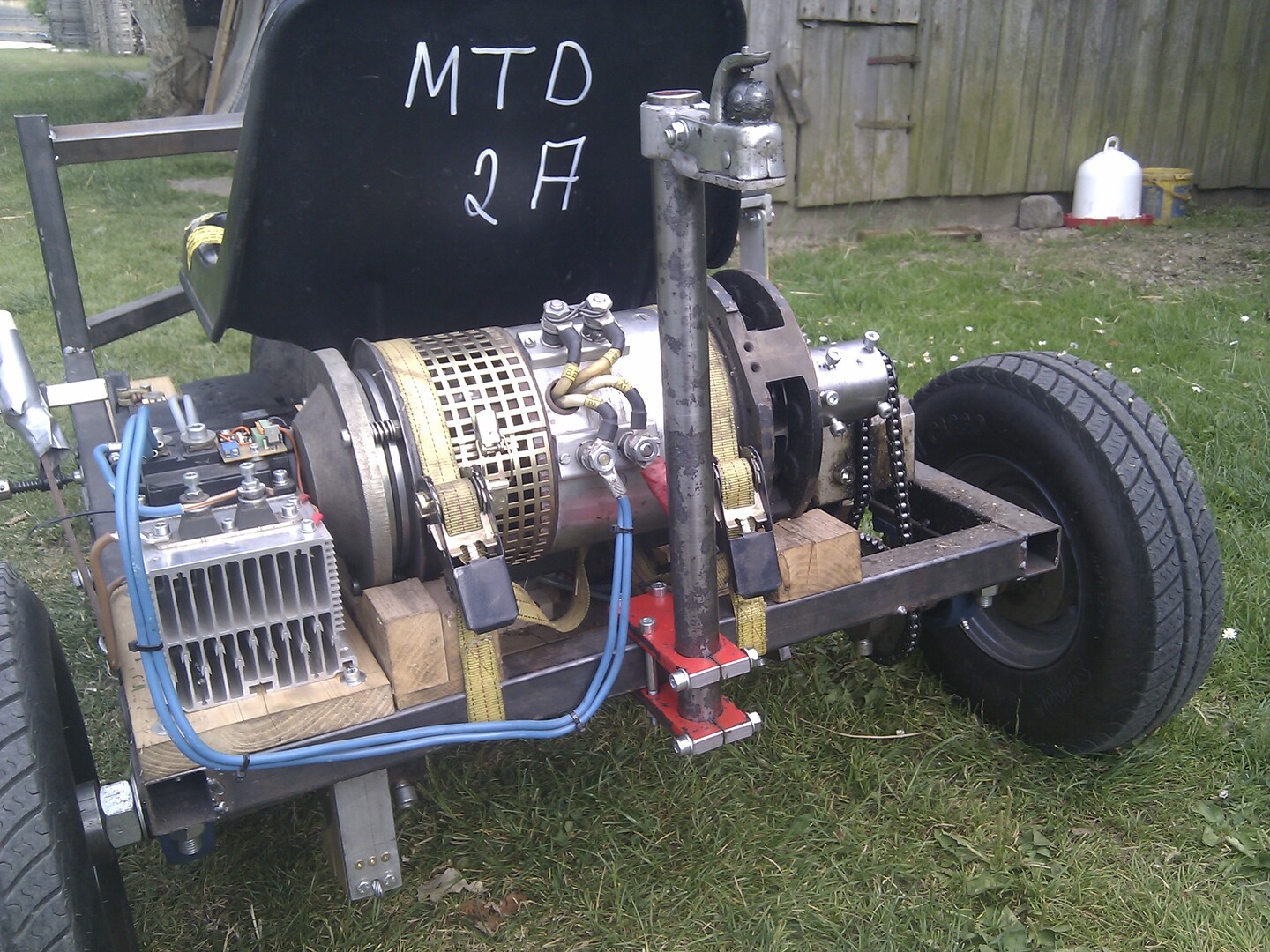

Motor

- Type: Serial wound DC motor

- Previous application: Forklift

- Power: 2,9 kW

- Voltage: 24 V

-

Current:

- Rated: 156 A

- Measured: 25 - 500 A

- Rotational speed: 1780 rpm

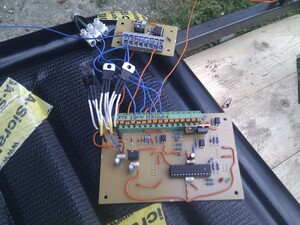

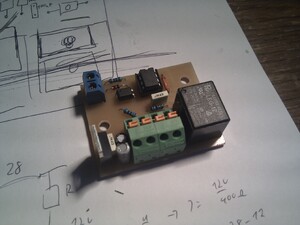

Control

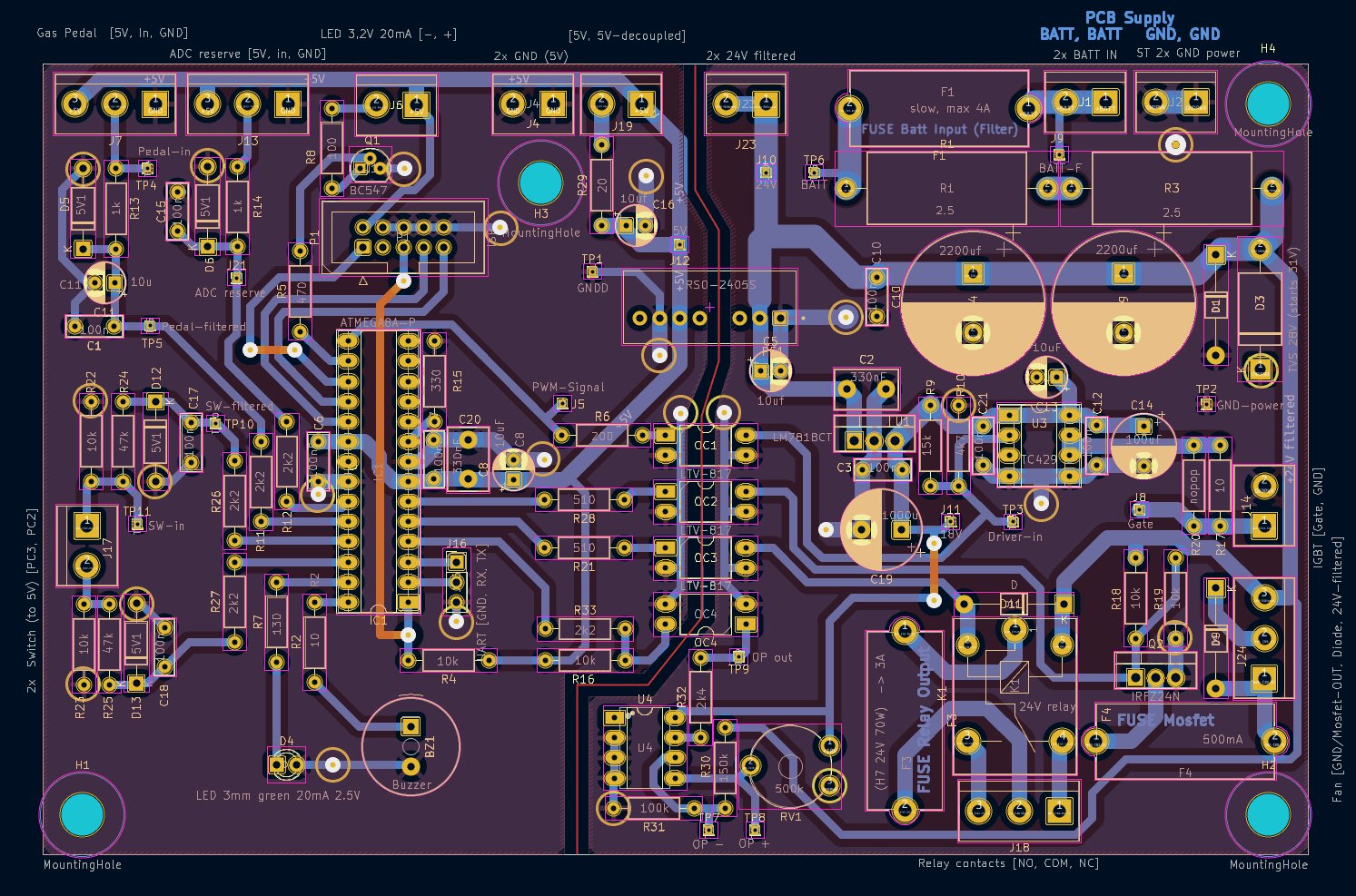

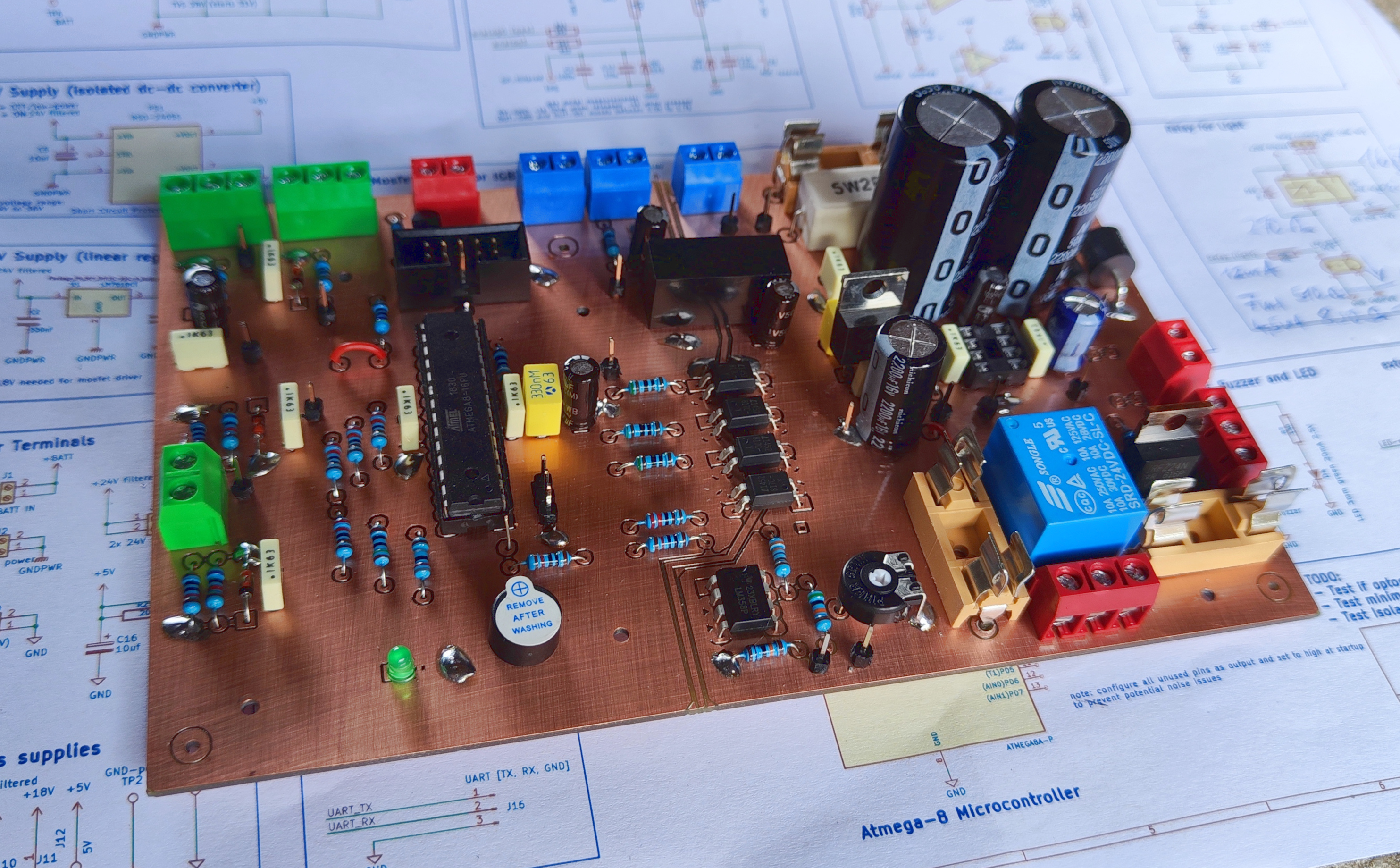

- Custom PCB with ATMEGA 8 microcontroller

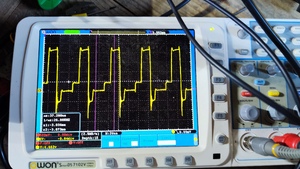

- Control method: 124 Hz PWM

- 600 A 1000 V IGBT (FUJI 1MBI600PX-140-01)

- Audi gas pedal

- Custom knife switch for direction selection

Mechanical

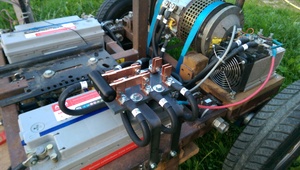

Drivetrain

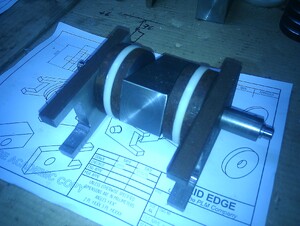

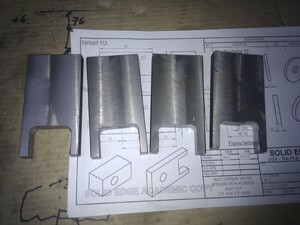

- Custom adapter from motor (helical cut spur gear) to sprocket for chain

- Chain: 06B-1(3/8’ x 7/32’)

- Sprockets:

- motor: Z13

- axle: Z40

Tires

- from car trailer

- 4.80/4.00-8

- Tubeless

- diameter 400 mm

Battery

- Voltage: 24 V (2x 12 V in series)

- Capacity: 2,4 kWh (2x 12 V 100 Ah)

- Type: Deep cycle AGM

Experience with battery types: Over the years different kinds of batteries were tested:

-

VRLA Starter battery

-

Positive: Very high discharge current

-> Noticably higher motor torque -

Negative: Fast loss of capacity when discharged too much and often

(bad deep cycle capability)

-

Positive: Very high discharge current

-

Lead GEL battery

- Positive: Suitable for very deep cycle applications (high actual usable capacity, with comparably less capacity loss)

-

Negative: Low discharge current

-> Significantly reduced torque in combination with this very current demanding motor (was almost unusable)

-

AGM deep cycle battery

- Slightly less discharge current than the Starter battery, but higher cycle stability

- Best option so far

-

Lithium-Ion battery?

As Experienced in the E-Bike and Armchair projects, Li-Ion would be the best type in terms of weight to capacity ratio and cycle stability.

But building a lithium-ion battery in the appropriate size for this project would simply be too expensive.

Electrical overview

The wiring of all components is documented in the following diagram:

Complete Document

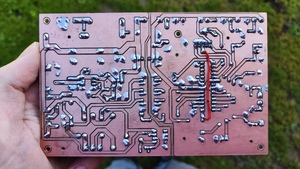

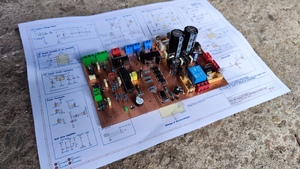

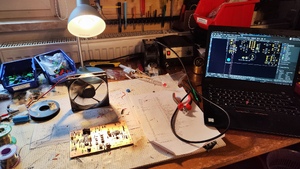

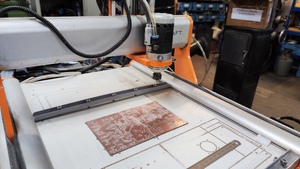

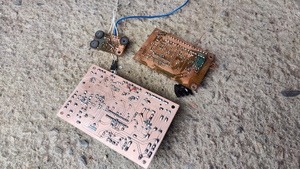

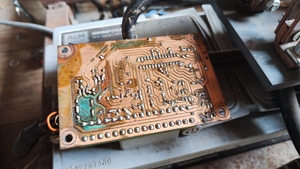

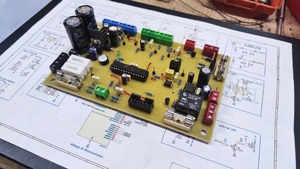

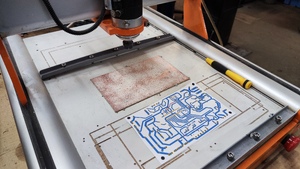

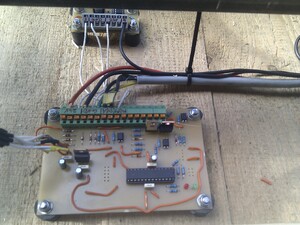

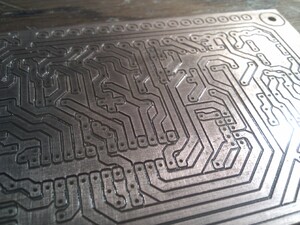

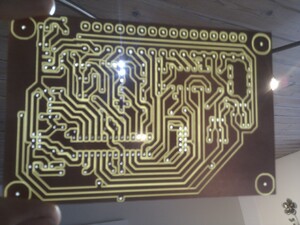

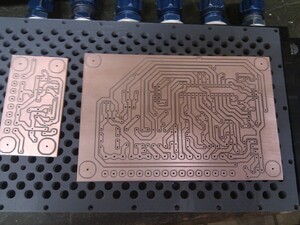

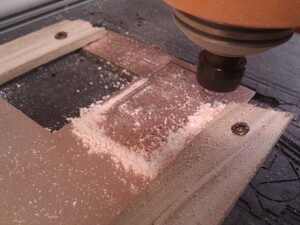

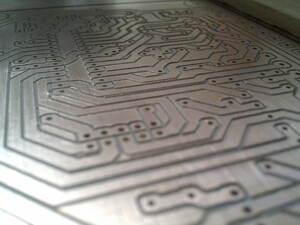

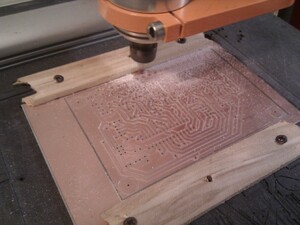

Control-PCB

An improved version of the pcb was created in 2024 replacing the first one from 2015.

For more details visit the repository containing all pcb versions: GitHub/electric-kart?#hardware-pcb-versions.

Schematic

Finished Schematic

Layout

3D Model

Firmware

The firmware for this pcb was programmed using the following components:

- C: Programming language

- avr-gcc: Compiler

- make: Software for controlling the compilation process

- AVRDUDE: Software for flashing the Atmel AVR microcontroller

- USB ISP Programmer: Hardware used as interface between pc and pcb

- FTDI board: UART-USB interface for debugging

The source code and pcb files are available on GitHub/electric-kart.

Videos

YouTube video

Tests

First test drive

2015.04.16

First motor test

2015.03.01

Suspension test

2015.12.10

Fails

Battery pole melts

2019.05.27

Short circuit

2015.12.10

Build process

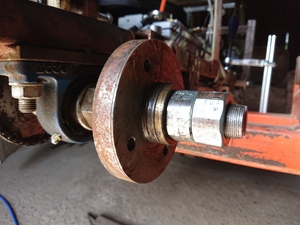

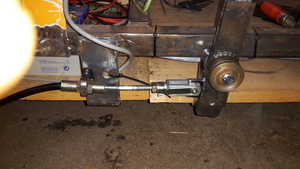

Axle thread cutting

2018.07.06

Casting battery pole

2019.06.01