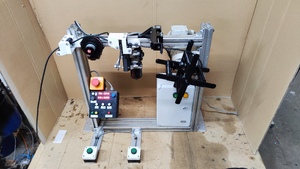

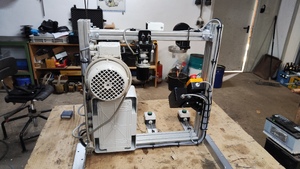

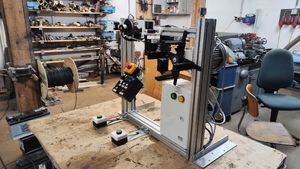

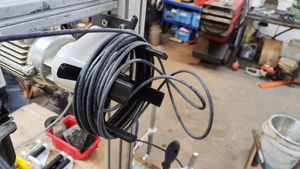

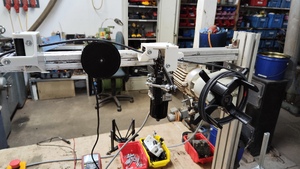

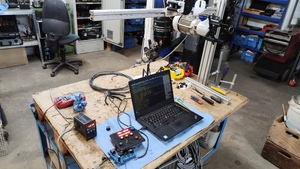

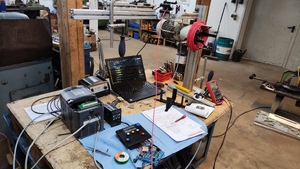

A custom built system that winds and cuts cable to a specified length. It is used for automating the repetitive process of creating multiple smaller cable packages from large 500 m spools for redistribution.

Details

- Power supply: 230 V 800 W

- Measuring accuracy: 0.0005 m

- Min Length: 0.5 m

- Max Length: 100 m

- Max Cable Diameter: 14 mm

- Speed: 2 m/s

-

Features:

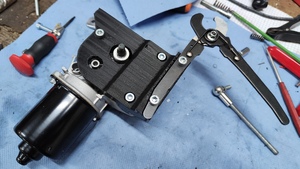

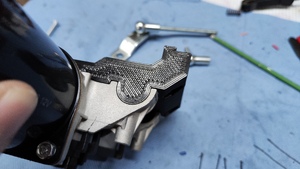

- Custom electric cable cutter

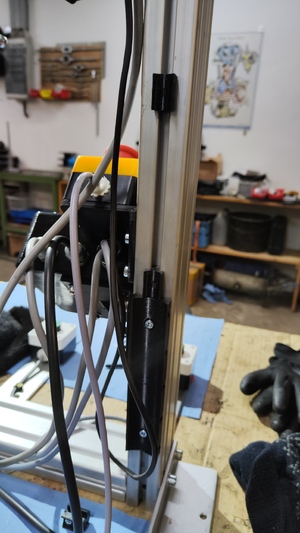

- Linear axis as guide for even winding

- 2-hand operation

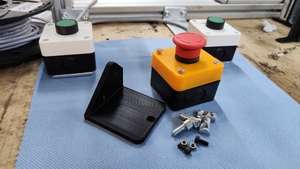

- Emergency switch

- Changeable cable reel

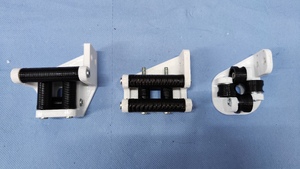

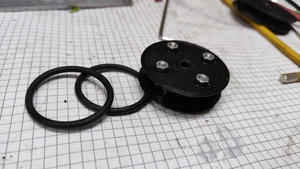

- Silent guide rolls with ball bearings

- Dynamic speed (slow start, slow end)

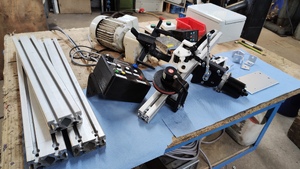

Components

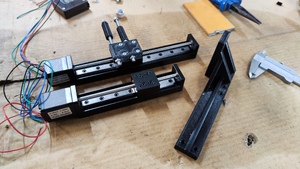

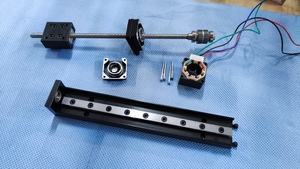

Mechanical

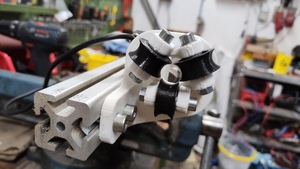

- Frame: 40x80 mm “Item” Aluminium profile

-

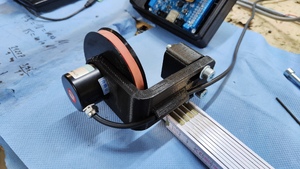

Linear guide:

- Model: T06

- Travel: 100 mm

- Pitch: 4 mm

-

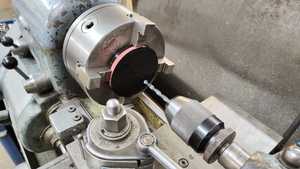

Metal components:

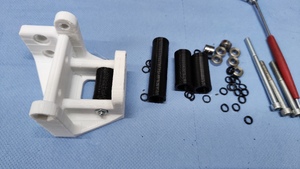

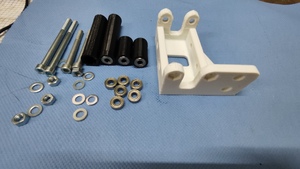

- 18x 6x13x5 mm ball bearings for rolls

- Various nuts and bolts

- Custom angle-iron parts and adapter plate

-

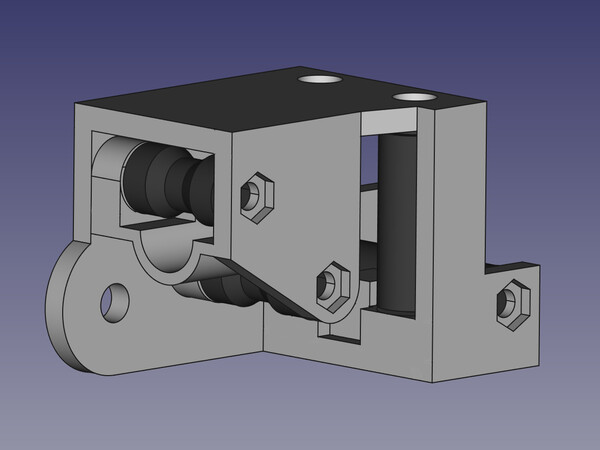

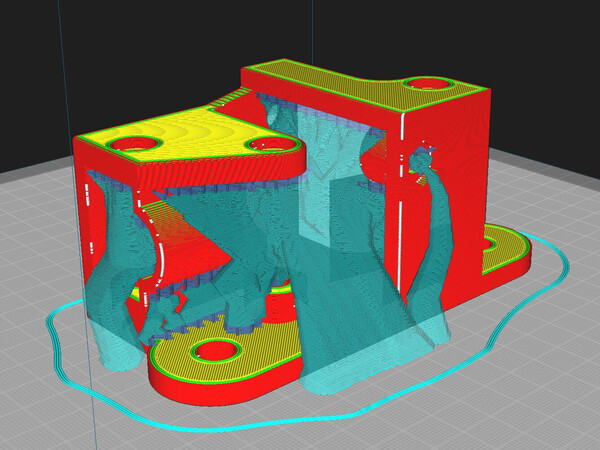

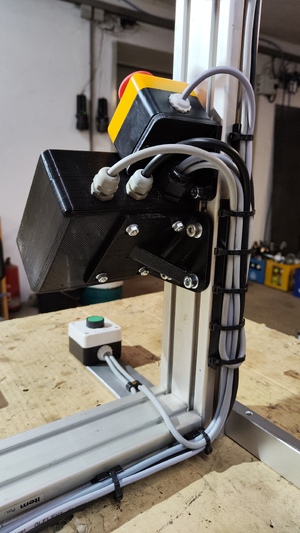

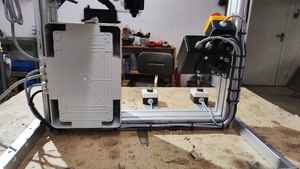

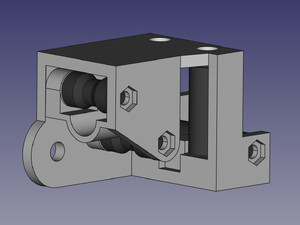

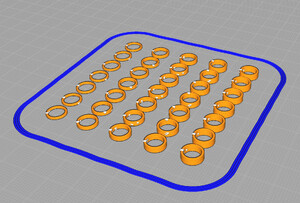

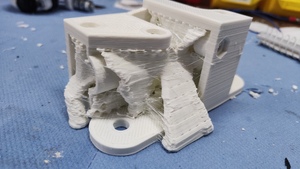

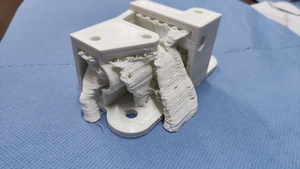

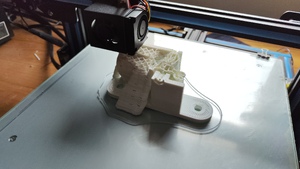

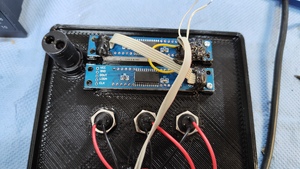

3D-printed Parts:

- Cable reel

- Guides, Rolls

- Control box

- Encoder mount

- Cutter main body

- Cable mounts

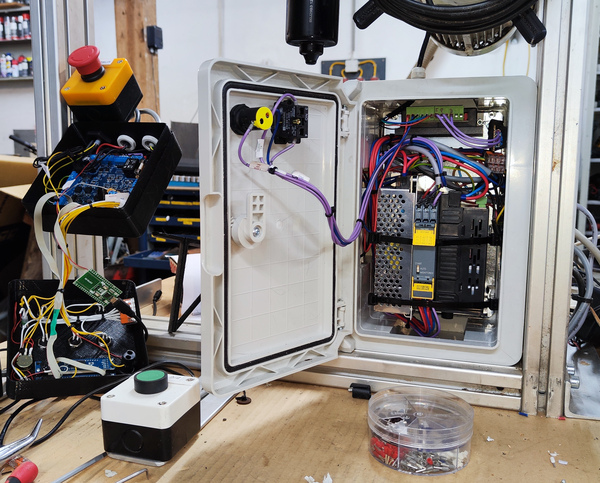

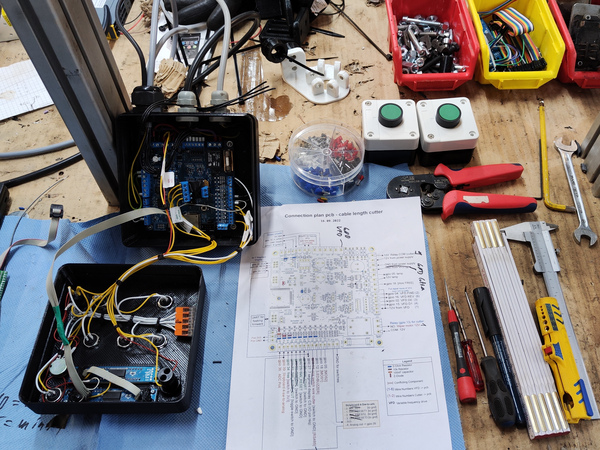

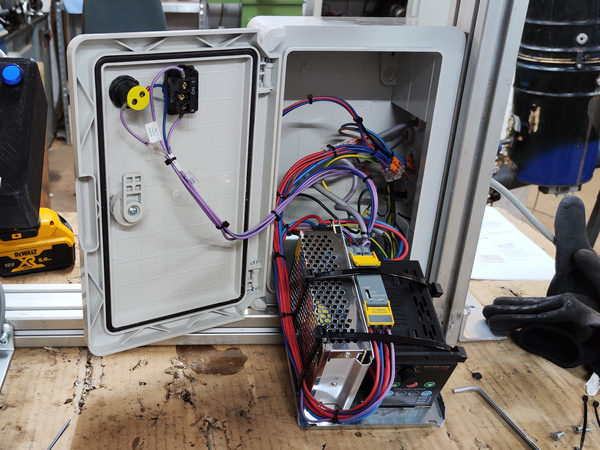

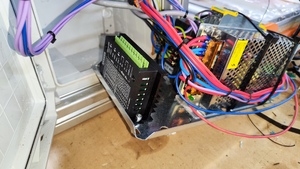

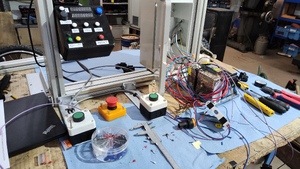

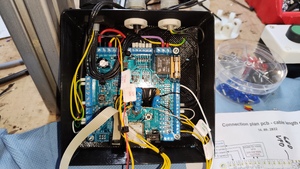

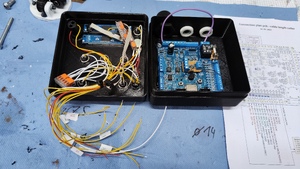

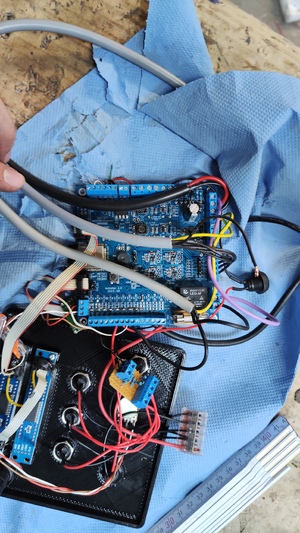

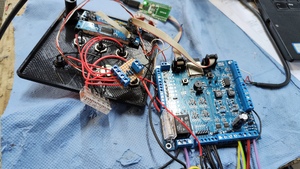

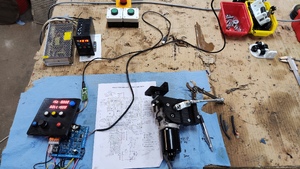

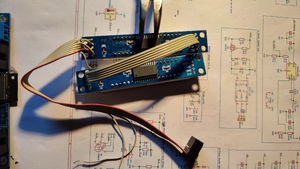

Electrical

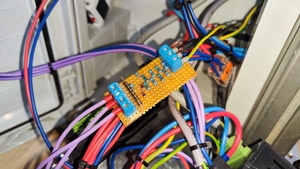

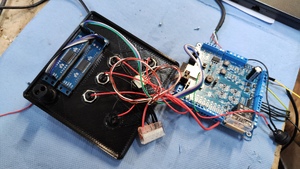

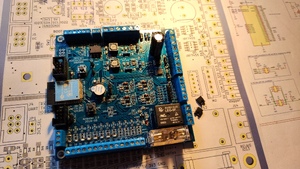

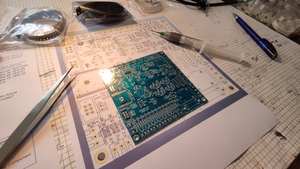

- Custom pcb with ESP-32 microcontroller

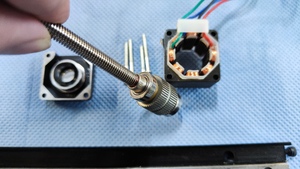

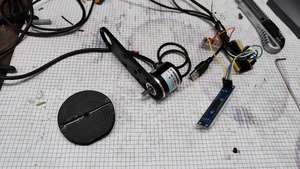

- Rotary encoder - LPD3806-600BM

- Three-phase motor - 0.3kW with 18:1 Gearbox

- Variable frequency drive (VFD) - T13-750W-12-h

- Stepper motor - Nema 12 28HB40 0.6 A

- Stepper driver - Microstep TB6600 9-42 V, 0.5-4 A

- Switching power supply - 12 V, 8 A

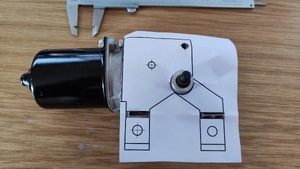

- Wiper motor

- Safety relay - Siemens 3SK1111-1AB30

- 2x 7-Segment display MAX7219

- Various push buttons and LED lights

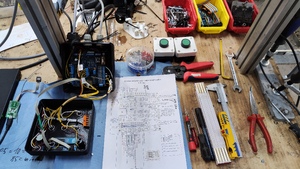

Course of action

Planning

All electrical aspects were planned in the following document:

Complete Document

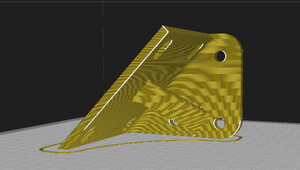

CAD

Most mechanical components in this project were 3D-printed. All 3D-printed parts were designed using FreeCAD, then sliced using Cura and printed on a CR-10 3D printer:

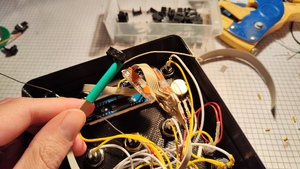

Wiring

The wiring was straightforward using the beforehand created connection plan.

Programming

The firmware for this custom pcb was created using the following components:

- Programming Language: C++

- Development Framework: ESP-IDF

- Flowchart Design: diagrams.net

- Version Control: Git

The repository with the source code and all relevant documents is available on GitHub

Videos

Tests

First setup

2022.08.18

Cutter

2022.09.02

Cable guide

2024.03.13

Without bearings

2022.09.17

Demonstration

Complete start

2022.09.30

Closeup

2022.09.30

Cable guide

2024.03.13