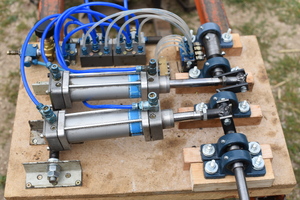

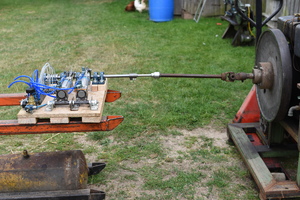

A 2 cylinder pneumatic motor powered by compressed air only.

This is a ‘just for fun project’, with no practical use. However it got quite some attention on YouTube.

Specification

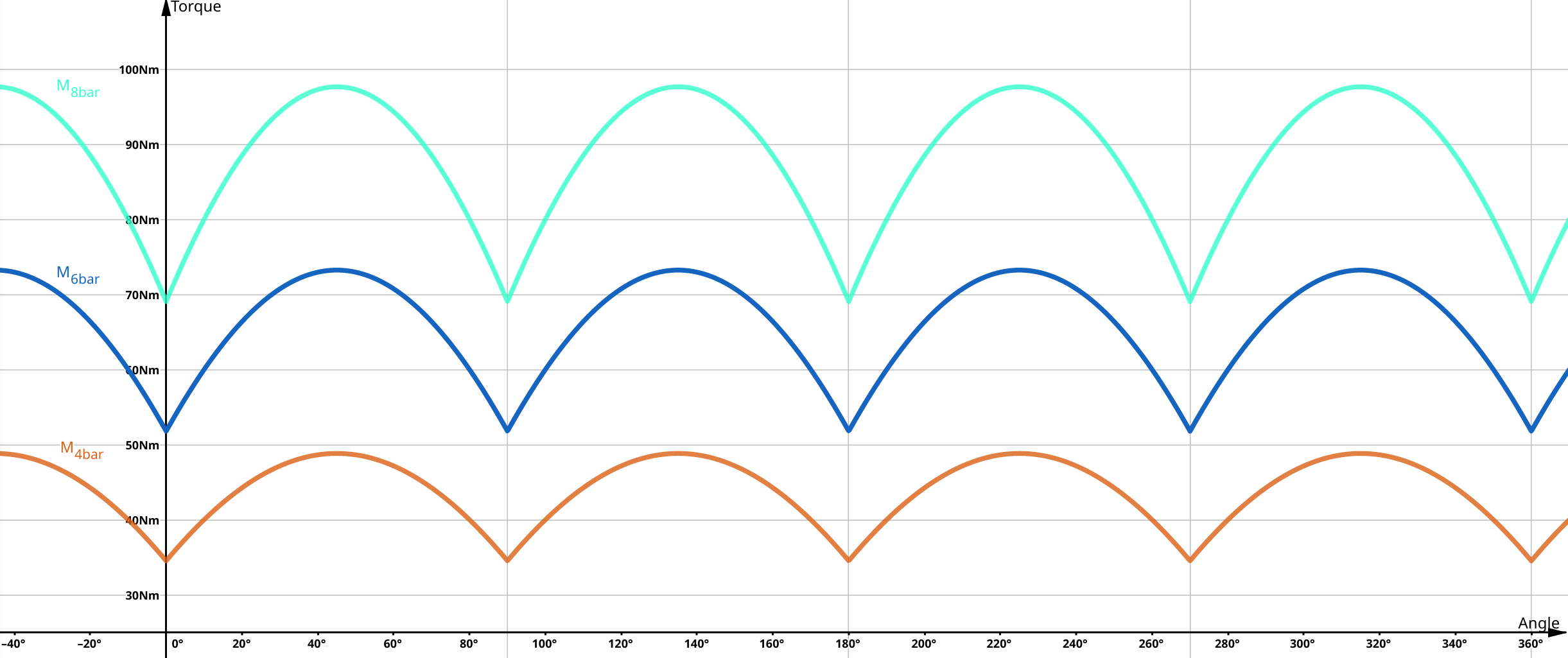

- Operating pressure: 3-8 bar

- Torque: 50-90 Nm at 6 bar

- Rotation speed: depends strongly on load and limits of air supply

Torque

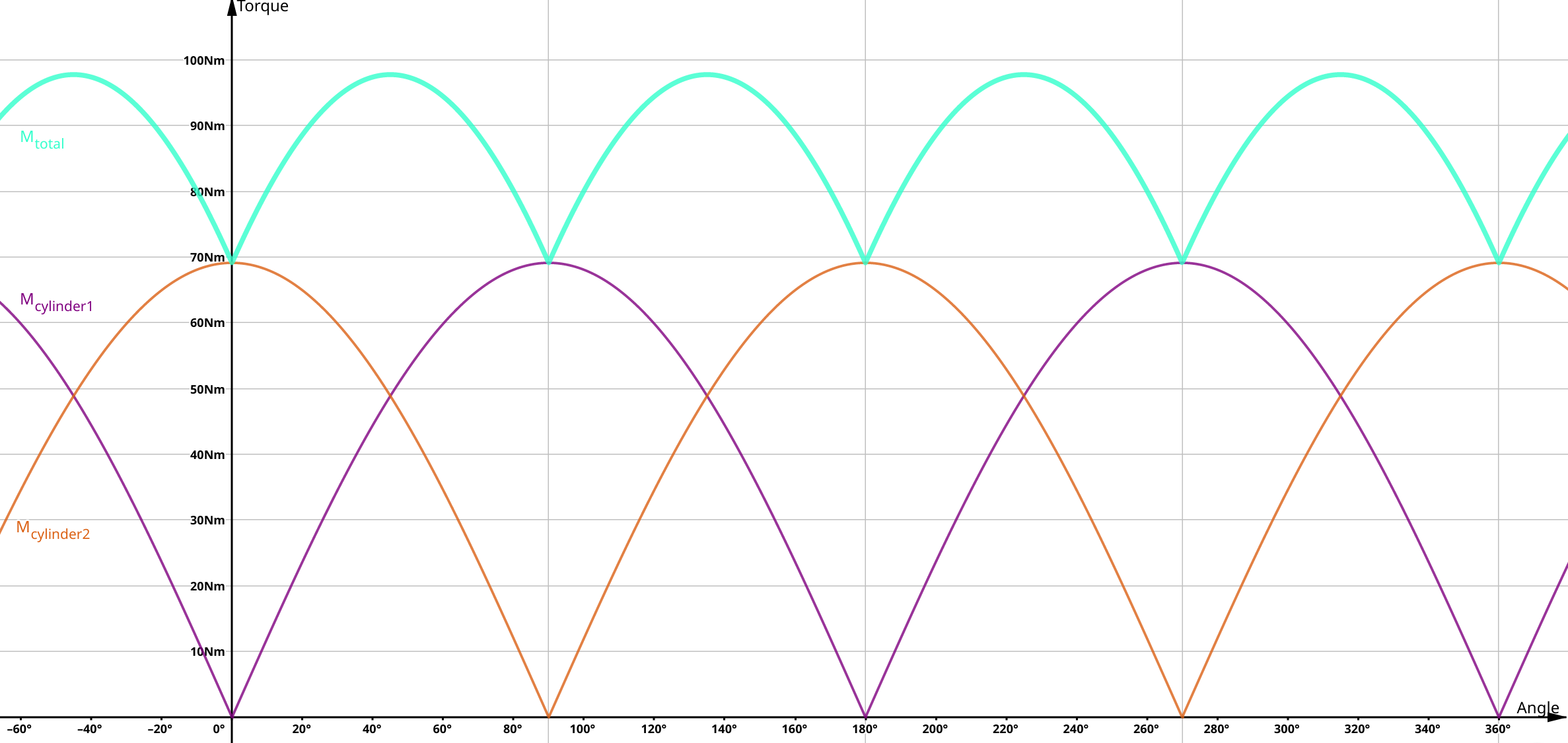

To get a rough idea of how much torque the motor provides and especially how stable it will run, i made some calculations.

The produced Torque depending on the crank angle is described by this very simplified function:

M(α) = 8bar * 1800mm² * 48mm * ( |sin(α)| + |sin(α+90)| )

Problems / Neglected aspects with this simplified approach:

- Different cylinder forces when extending and retracting (due to different effective surface area)

- Friction losses

- Pressure is not constant when there is movement

Torque vs Angle graph at 8 bar

Because double acting cylinders are used and the chosen 90 degree offset between the two cranks, this motor runs quite smoothly and there are no torque gaps at any angle.

Torque vs Angle at different pressures (4 bar, 6 bar, 8 bar)

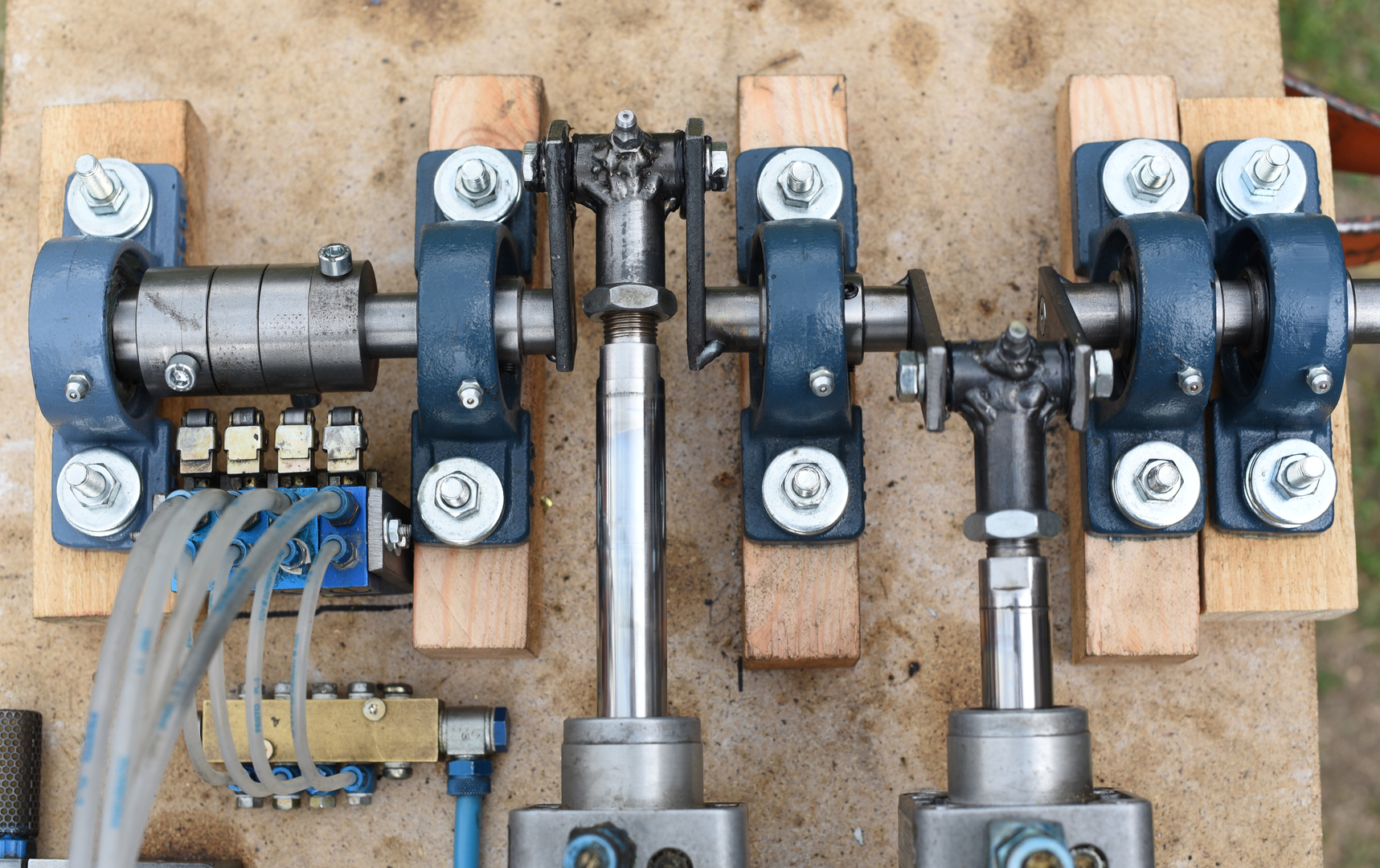

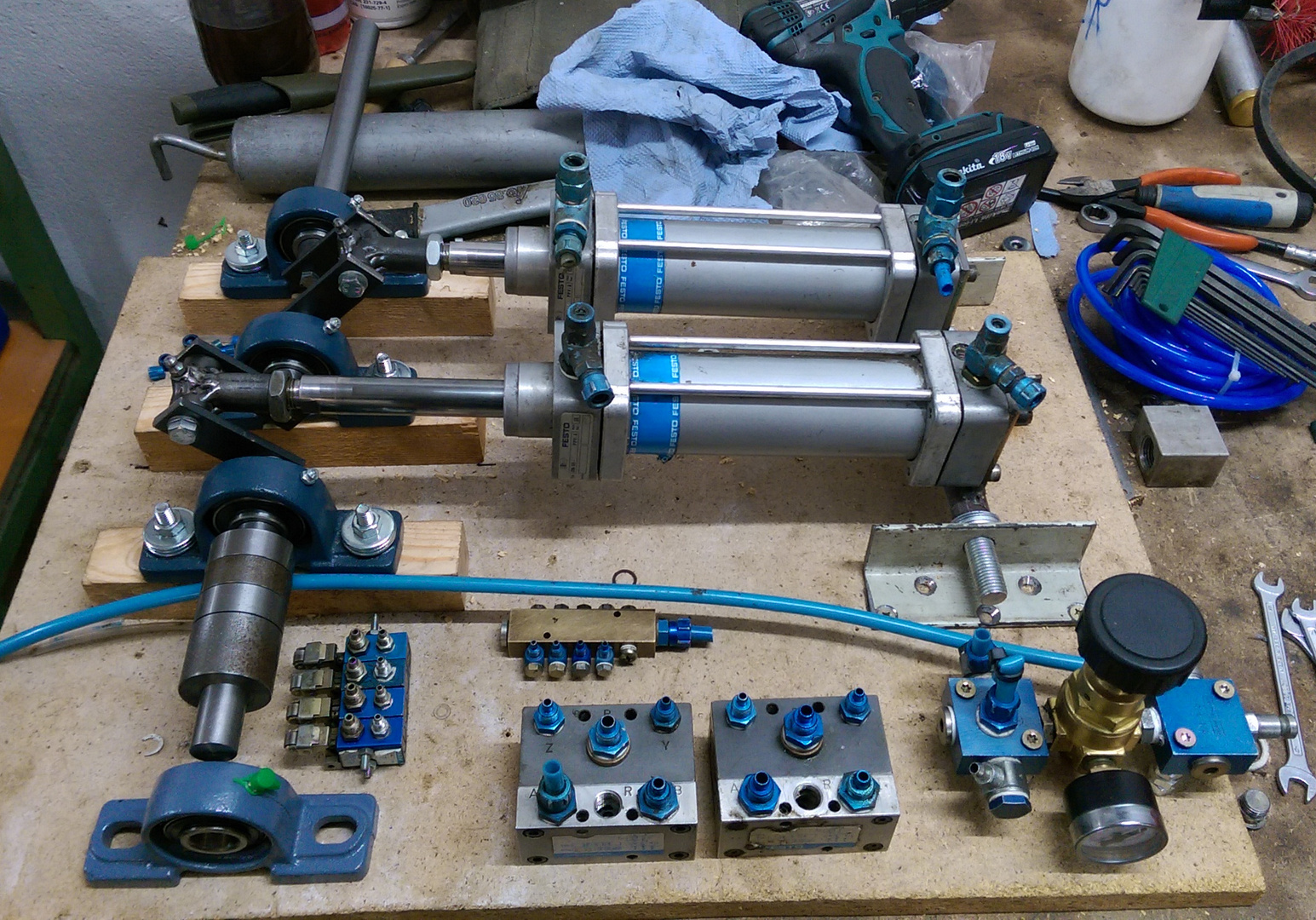

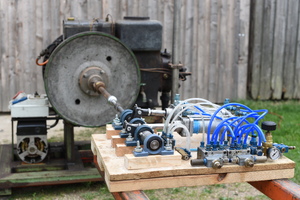

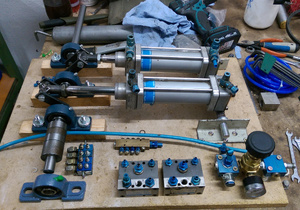

Components

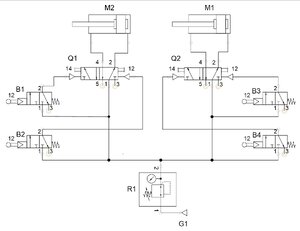

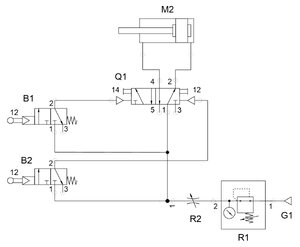

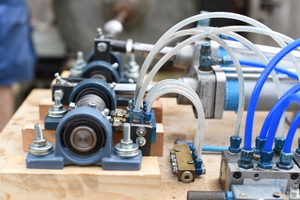

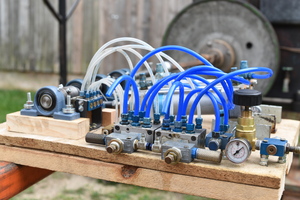

Pneumatic

- 2x Compressed Air Cylinder

- 2x Bistable 5/2-Way-Valve controlled by air pressure

- 4x 3/2-Way-Valve with Roller

- 1x Pressure regulating Valve

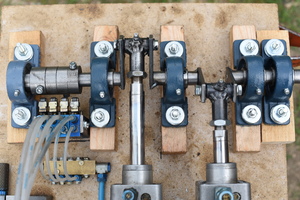

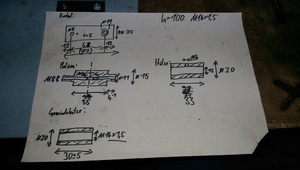

Mechanical

- 5x 20 mm bearing block

- Wodden baseplate

- Custom crank

- Custom timing-rings for actuating the valves