Homemade automated system for heating the workshop using wood chips.

During longer sessions in the workshop, while it’s cold outside, it gets quite annoying to refill the stove with pieces of wood frequently.

With this project that process got automated, the stove is fed automatically and can run for hours without manual intervention.

Specification

- Fuel type: Wood chips, sawdust, paper

- Storage capacity: 70 L

- Temperature range:

-

Rotational speed:

- Auger: 50 rpm

- Agitator: 26 rpm

Features

- Agitator: Reliably forces chips from tank into auger

- Regulates exhaust gas to defined temperature

- Modes of operation:

- Always off

- Always on

- Simple temperature control

- Smart control (default)

- Smart control:

- Attempt for optimal and fast regulation to target temperature of a very delayed system

- Fuel amount gets dynamically adjusted

- Detects important states of the fire or system and acts accordingly:

- Fuel empty

- Fire went out

- Too much fuel

- Burning in pipe

- 7 Segment display:

- menu to set target temperature and other parameters

- current temperature

- text notifications

- Buzzer for acoustic notifications

Components

Mechanical

- Old furnace

- Custom adjustable frame using 40x40x2 mm iron square tube

- Steel pipe d=120 mm

- Auger d=60 mm, l=900 mm

- Storage tank using two steel buckets

- Motor

- Type: Three-phase 400V

- Power: 90 W

- Speed: 1380 rpm

- Gearbox

- Type: HEYNAU G2V39M

- Reduction: i=32

- Torque: 20 Nm

- Custom coupling (motor -> auger)

- Chain drive for Agitator

- Gear Motor: 16 teeth

- Gear Shaft: 49 teeth

- Chain 06-B (3/8x7/32)

- Agitator

- 20mm shaft

- 2x 20mm bearing

- metal bar clamped onto flattened shaft

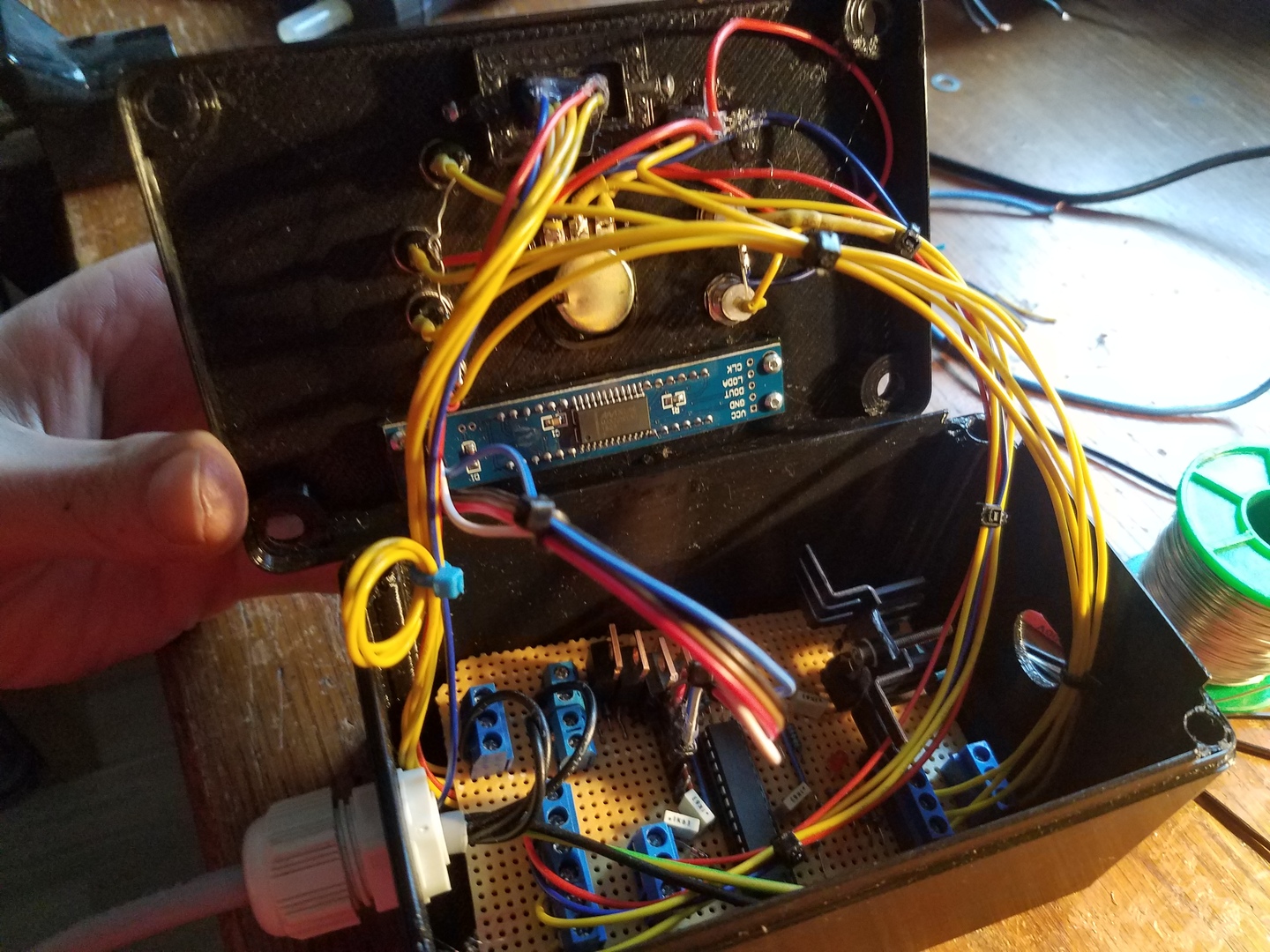

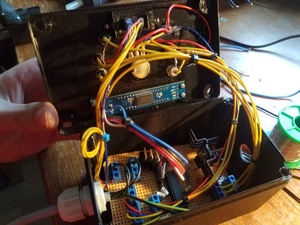

Control

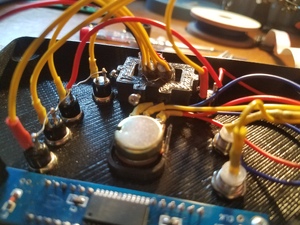

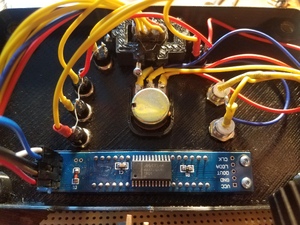

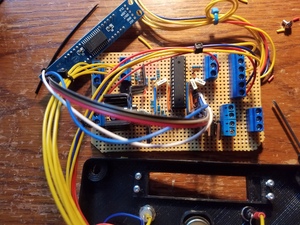

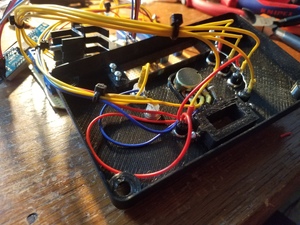

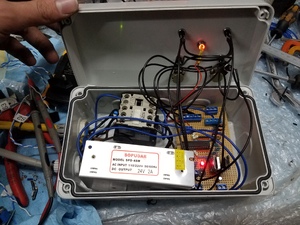

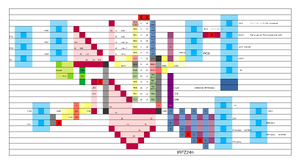

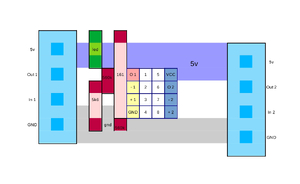

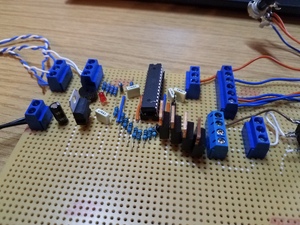

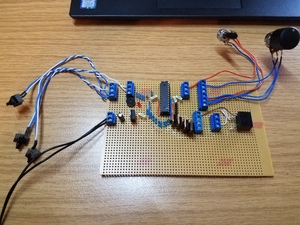

- Custom strip board

- Atmega8 microcontroller

- 3d-printed housing

-

Input

- Potentiometer

- 3x Momentary switch

-

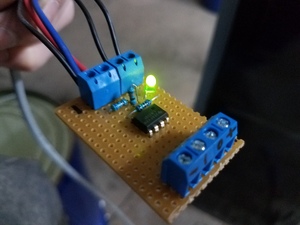

Sensors

- Thermocouple in exhaust pipe with custom amplification circuit

-

Output

- 8 digit 7-segment display (via spi bus)

- 2x 5mm LED

- Buzzer

- 3x mosfet output for future extensions

- 12V contactor

Failed Attempts

Before the current, final solution, multiple approaches were tested:

Spring auger

Problems

- Flexible and small diameter spring gets pushed away in tube, and does not convey the chips

- Long spring tends to get stuck at the end and stats tangling itself

Pneumatic piston

Problems

- Chips get stuck between piston and pipe opening often

- Instead of conveying, the chips get compressed in the pipe (like a press for wooden briquets)

- Limited force of the pneumatic cylinder

Pneumatic agitator

Problems

- Unnecessary noise (exhaust and valves are loud)

- Unreliable - After certain time the Chips are stuck above the auger anyways

- Manual intervention is necessary sometimes

Agitator with springs

Problems

- Springs get bent by the permanent stress

- Springs tend to build tension and throw chips out of the tank at certain fill level

- Unreliable - Springs never reach down to the auger, thus can clog below

Control without sensor

Problems

- No way to detect whether the fire went out

- Hard to find correct interval settings (wait and run time of the motor)

- No way to compensate changes in fuel type/quality

Videos

Timelapse

2019.10.29

Agitator test - Rod

2021.12.04

Display test

2018.11.24

Agitator test - Springs

2017.04.30

Cylinder test

2016.03.07

Gallery

PREVIOUSShifter Kart

NEXT49ccm Scooter