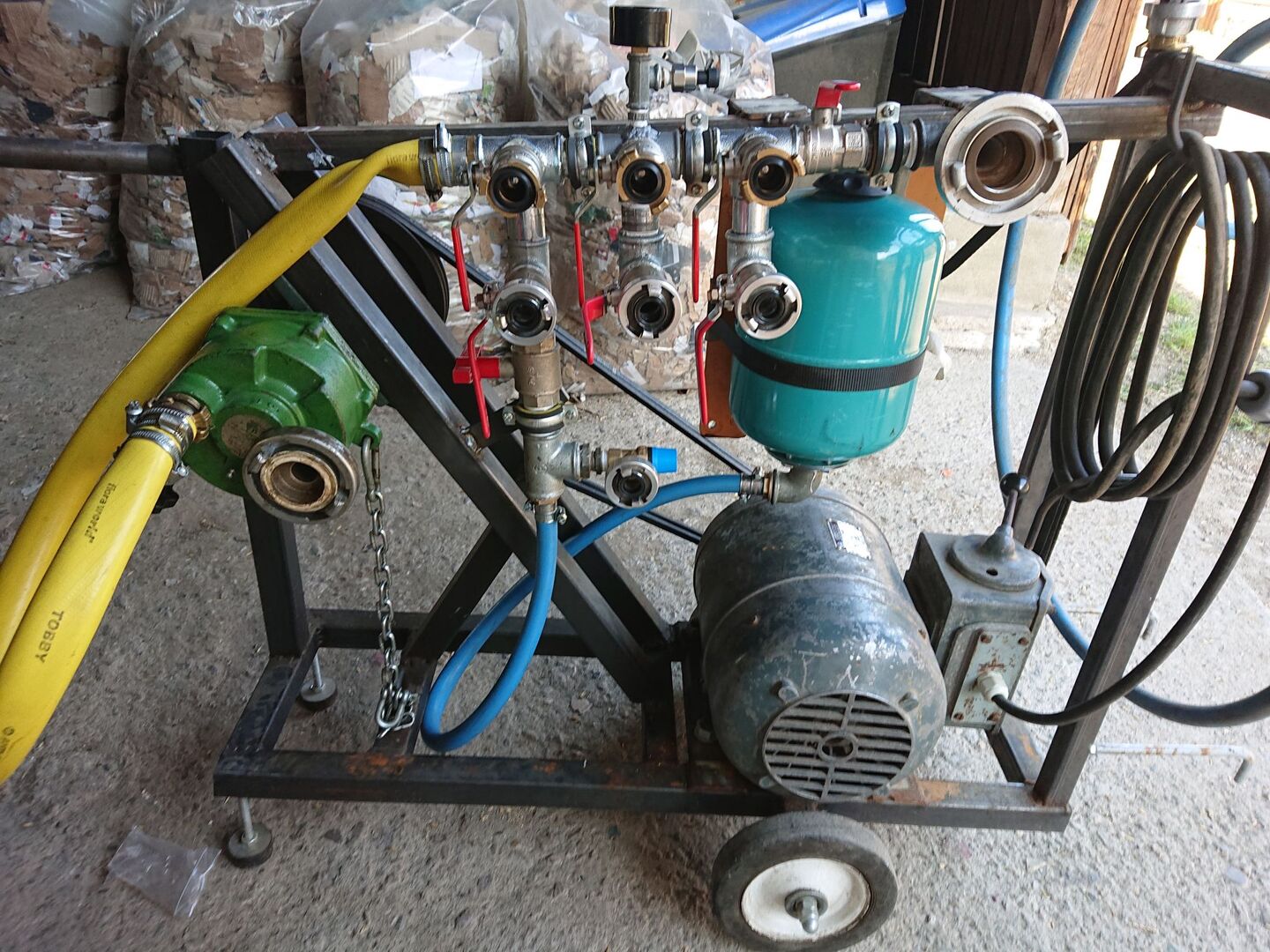

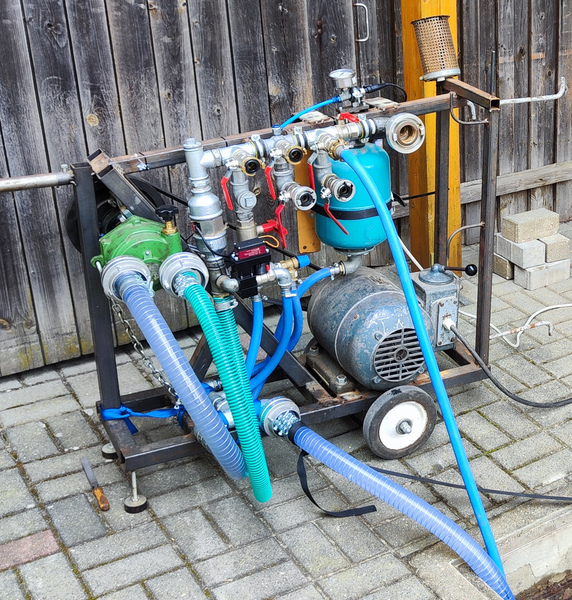

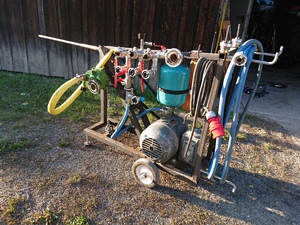

Custom Build with a PTO driven water pump electrically powered and pressure regulated.

This project transforms a PTO (Power Take-Off) pump, intended for tractors, into an electrically driven system. The system features a pressure and flow sensor, with a microcontroller controlling a bypass valve and a 4 kW electric motor.

Reasons for this project

Why choose PTO Pump?

- Enhanced Performance: Significantly higher pressure (typical 25 bar vs 5 bar) and flow capabilities compared to commonly available pump systems

- Versatility: The same pump can still be used with a tractor when needed

Why automate it?

- Noise Reduction: Minimize noise level by operating the pump only as fast as necessary

- Energy Efficiency: Optimize power consumption by reducing motor speed and pressure

- Flexible Control: Microcontroller-driven system allows for easy integration of additional features (e.g. timeouts, remote-control)

Components

Mechanical

-

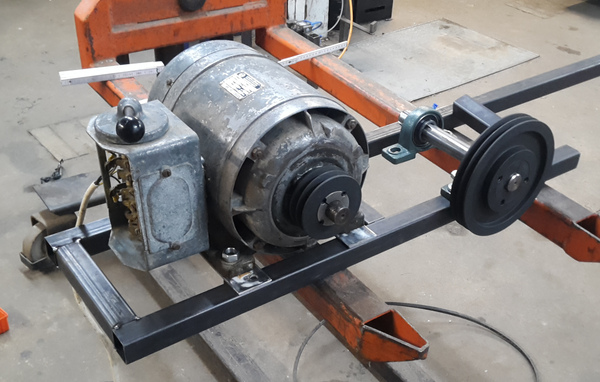

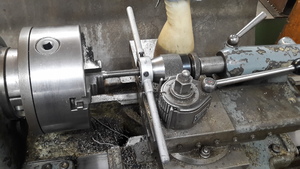

Belt drive

- Pulley motor: 2x13mm, d=100mm

- Pulley PTO-shaft: 2x13mm, d=250mm

- 2 x 13mm v-belt

- Expansion tank: 8 Liter

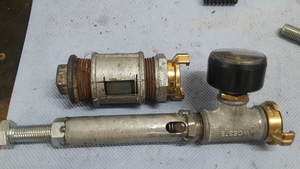

- Bypass valve: 3/4”

- Pressure relief valve: 10 bar

- PTO Shaft: 1 3/8” (34.9 mm)

- Bearings: 2x 35 mm roller bearings with clamping sleeve

- Various fittings, valves, couplings…

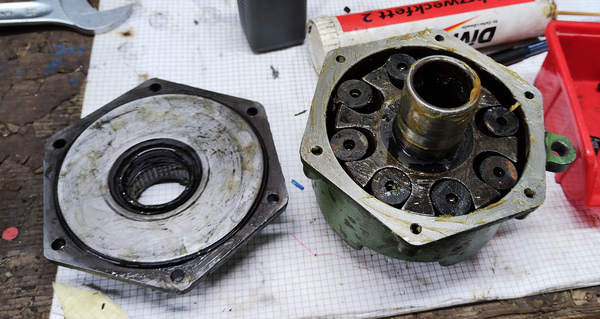

Pump

- Name: ML 20

- Power: 4 kW

-

Rotational speed:

- Max: 700 rpm

- Rated: 540 rpm

- Connection: 1 3/8”, 6 Tooth PTO shaft

- Max. Pressure: 25 bar

-

Flow rate:

- Low pressure: 180 l/min

- High pressure: 70 l/min

Motor

- Rated power: 4 kW

- Rotation speed: 1415 rpm

- Voltage: 380 V

- Frequency: 50 Hz

- Type: Three phase asynchronous motor

- Attachment: Star-delta cam switch

- Previous application: Powering a stationary thresher

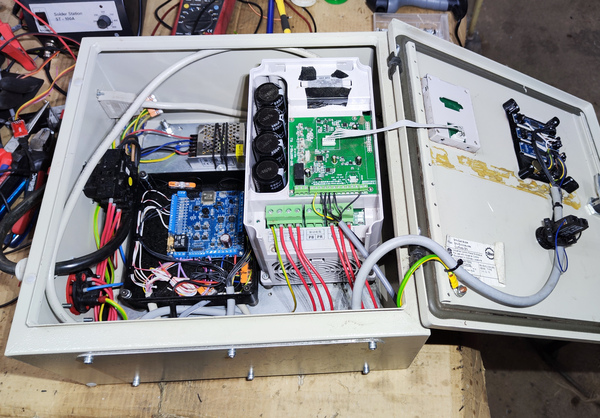

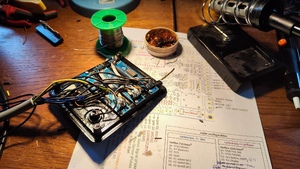

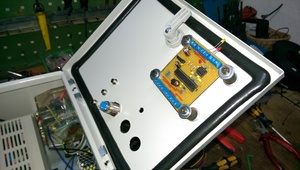

Control

- Controller: Custom pcb with ESP-32 microcontroller

- Switching power supply: 12 V, 2 A

- VFD: 7.5 kW variable frequency drive

- Servo motor: DS51150-12V 150 kg

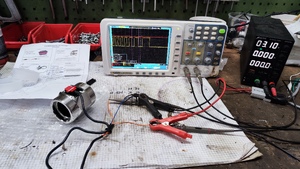

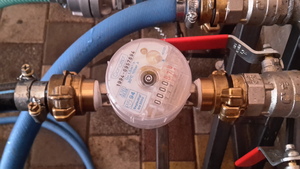

- Pressure sensor: Analog 5 V, 0-34.5 bar (500 psi)

- Flow sensor: Size 2”, 5-24 V, 10-200 L/min, 12 Pulses per Liter

Features

-

Regulation

- Speed Control: Automatically adjusts motor speed to match the water demand using the VFD

- Pressure Regulation: Maintains consistent pressure output using PID control manipulating the bypass valve with a servo motor

-

User Interface

-

Hardware Interface:

- Start/stop and set target pressure using buttons

- View sensor data on 7 segment display

-

Web Interface:

- Control pump remotely

- View data history

-

Hardware Interface:

-

Smart Control

- Auto Power Down: Enters power-saving mode during inactivity

- Dynamic pressure: Reduces Pressure when no water is used

Electrical overview

All electrical aspects were planned in the following document:

Complete Document

Firmware

The firmware for the esp32 on the custom pcb was created using the following components:

- Programming Language: C++

- Development Framework: ESP-IDF

- Flowchart Design: diagrams.net

- Version Control: Git

The repository with the source code and all relevant documents is available on GitHub

Videos

First test (motor, frame)

2018.05.11 - First test of the welded frame and old motor:

Test hardware UI

2024.05.21 - Set target pressure and start the pump using potentiometer and buttons:

Start with phone

2024.05.21 - Set target pressure, start and check data using the web interface:

Test valve, motor control

2024.05.21 - Motor speed and valve position are automatically adjusted to achieve the desired pressure while varying the water flow: